Nitrogen compressors are specifically designed to compress nitrogen gas, increasing its pressure for various applications. Nitrogen is an inert gas that is widely used in industries such as manufacturing, pharmaceuticals, electronics, food processing, oil and gas, and many others. Compressing nitrogen gas is necessary for tasks such as storage, transportation, and specific industrial processes.

Nitrogen compressors are typically used in nitrogen generation systems, where they take in atmospheric air and separate nitrogen from other gases using methods like pressure swing adsorption (PSA) or membrane separation. Once the nitrogen is separated, the compressor is employed to raise its pressure to the desired level.

The compressed nitrogen gas can then be utilized in a range of applications, such as:

1. Inerting: Nitrogen is often used for purging or displacing oxygen in containers, tanks, pipelines, or storage spaces to prevent oxidation, combustion, or degradation of sensitive materials.

2. Pressurization: Compressed nitrogen is employed to pressurize systems, such as pneumatic tools, laboratory equipment, or aircraft tires.

3. Cooling: Compressed nitrogen is used in cryogenic applications for cooling, such as in the semiconductor industry or for liquefying gases.

4. Blanketing: Nitrogen is used to create an inert atmosphere by blanketing or covering materials to prevent contact with oxygen or moisture, thus preserving their quality and preventing oxidation.

5. Leak Testing: Compressed nitrogen can be utilized for leak testing and pressure testing of various systems, equipment, or pipelines.

Nitrogen compressors come in different types and configurations, as mentioned in the previous responses, to accommodate various flow rates, pressure requirements, and specific application needs. The selection of a nitrogen compressor depends on factors such as the required pressure, flow rate, purity, reliability, efficiency, and specific industry requirements.

It's important to consult with experts in compressed air systems or nitrogen generation to determine the most suitable nitrogen compressor for your specific application.

Types of nitrogen compressors

There are several types of nitrogen compressors available, each designed for specific applications and operating conditions. Here are some common types of nitrogen compressors:

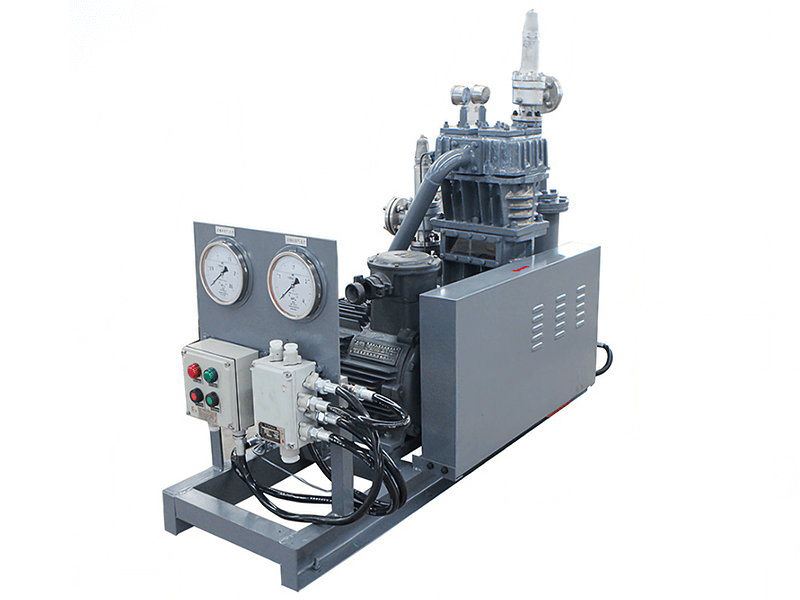

1. Reciprocating Compressors: Reciprocating compressors, also known as piston compressors, are widely used in various industries, including nitrogen generation systems. They operate by using a piston within a cylinder to compress the gas. Reciprocating compressors can be either single-stage or multi-stage, depending on the pressure requirements.

2. Screw Compressors: Screw compressors are rotary-type compressors that utilize two interlocking helical rotors to compress the gas. They are known for their continuous and smooth operation, making them suitable for high-capacity nitrogen compression applications. Screw compressors are efficient and have a relatively low noise level.

3. Centrifugal Compressors: Centrifugal compressors are dynamic compressors that use high-speed rotating impellers to accelerate the nitrogen gas and increase its pressure. They are commonly used in large-scale nitrogen generation and industrial applications where high flow rates and high-pressure ratios are required. Centrifugal compressors are known for their compact design, low maintenance requirements, and high efficiency.

4. Scroll Compressors: Scroll compressors are a type of positive displacement compressor that uses two spiral-shaped scrolls to compress the gas. They are widely used in smaller-scale nitrogen generation systems and applications that require lower flow rates and pressures. Scroll compressors are compact, quiet, and have fewer moving parts, resulting in reduced maintenance needs.

5. Diaphragm Compressors: Diaphragm compressors are specifically designed for handling gases that need to be isolated from the compressor's lubricating oil or other contaminants. These compressors use a flexible diaphragm to compress the gas, and they are commonly used in industries where purity is critical, such as in the production of high-purity nitrogen for laboratory applications or the semiconductor industry.

6. Turbo Compressors: Turbo compressors, also known as turboexpanders, are primarily used in cryogenic applications where nitrogen needs to be compressed or expanded at very low temperatures. These compressors use a combination of high-speed rotating impellers and diffusers to achieve the desired compression or expansion of the gas.

7. Liquid Ring Compressors: Liquid ring compressors use a rotating impeller and a liquid ring to compress the nitrogen gas. They are commonly used in applications where the gas contains liquids or vapors that need to be removed during compression. Liquid ring compressors are efficient and can handle wet or saturated gases effectively.

8. Scroll Boosters: Scroll boosters, also known as booster compressors, are used in conjunction with other primary compressors to increase the pressure of the nitrogen gas. They work by taking in the low-pressure gas from the primary compressor and compressing it further before it enters the downstream system. Scroll boosters are compact and provide additional pressure boost for specific applications.

9. Axial Compressors: Axial compressors are dynamic compressors that use a series of rotating blades to compress the nitrogen gas. They are commonly used in large-scale industrial applications where high flow rates and relatively lower pressure ratios are required. Axial compressors are known for their high efficiency and are often used in nitrogen generation systems for oil and gas industries.

10. Magnetic Bearing Compressors: Magnetic bearing compressors use magnetic levitation technology to support the rotating components, eliminating the need for traditional mechanical bearings. These compressors offer advantages such as reduced friction, improved efficiency, and lower maintenance requirements. Magnetic bearing compressors are used in various nitrogen compression applications, particularly in industries where precision, reliability, and energy efficiency are crucial.

11. Hybrid Compressors: Hybrid compressors combine different compression technologies to optimize performance and efficiency. They may incorporate elements of reciprocating, screw, or centrifugal compressors to achieve specific compression requirements. Hybrid compressors are often utilized in nitrogen generation systems where a combination of high flow rates and pressures is required.

It's important to note that the suitability of a nitrogen compressor type depends on the specific requirements of the application, such as flow rate, pressure range, purity, energy efficiency, and environmental conditions. Consulting with experts in the field or compressor manufacturers can help determine the most appropriate type of nitrogen compressor for a particular application.

Prices of different nitrogen compressors

The prices of nitrogen compressors can vary significantly based on factors such as the type of compressor, brand, capacity, features, and market conditions. It's important to note that the following price ranges are approximate and can vary across different regions and suppliers. Additionally, prices may change over time. Here are some general price ranges for nitrogen compressors:

1. Reciprocating Compressors: Prices for reciprocating compressors can range from a few hundred dollars for small, low-capacity models to several thousand dollars for larger, higher-capacity industrial-grade compressors. Prices can vary based on the compressor's power rating, number of stages, and additional features.

2. Screw Compressors: Screw compressors are typically more expensive compared to reciprocating compressors. Prices can start in the low thousands of dollars for smaller capacity models and can go up to tens of thousands of dollars for larger industrial-grade screw compressors.

3. Centrifugal Compressors: Centrifugal compressors are usually the most expensive among the nitrogen compressor types. Prices can range from tens of thousands to hundreds of thousands of dollars, depending on the capacity, pressure ratio, and specific requirements of the application.

4. Scroll Compressors: Scroll compressors are generally more affordable compared to other types. Prices can range from a few hundred dollars for smaller capacity models to a couple of thousand dollars for larger capacity scroll compressors.

5. Diaphragm Compressors: Diaphragm compressors are often used in specialized applications and are priced accordingly. Prices can vary from a few thousand dollars for smaller laboratory-grade compressors to tens of thousands of dollars for larger industrial-grade diaphragm compressors.

6. Turbo Compressors: Turbo compressors, especially those used in cryogenic applications, are typically high-end and specialized equipment. Prices can be in the range of tens of thousands to hundreds of thousands of dollars, depending on the specific requirements and operating conditions.

7. Liquid Ring Compressors: Prices for liquid ring compressors can vary depending on the capacity and specific application requirements. Smaller capacity models may start around a few thousand dollars, while larger industrial-grade liquid ring compressors can range from tens of thousands to hundreds of thousands of dollars.

8. Scroll Boosters: Scroll boosters are typically more affordable compared to primary compressors. Prices can range from a few hundred dollars for smaller capacity models to a few thousand dollars for larger capacity boosters.

9. Axial Compressors: Axial compressors are commonly used in large-scale industrial applications, and their prices reflect their capacity and performance. Prices can range from tens of thousands to hundreds of thousands of dollars, depending on the specific requirements and operating conditions.

10. Magnetic Bearing Compressors: Magnetic bearing compressors are advanced and high-performance compressors, and their prices tend to be higher compared to traditional compressor types. Prices can range from tens of thousands to hundreds of thousands of dollars, depending on the capacity, features, and brand.

11. Hybrid Compressors: Hybrid compressors are typically customized solutions that combine different compression technologies. Prices for hybrid compressors can vary significantly based on the specific configuration, capacity, and features. It's best to consult with manufacturers or suppliers to get accurate pricing information for hybrid compressors.

Remember that the prices mentioned above are approximate and can vary based on multiple factors, including the specific requirements of the application, optional features, brand, and market conditions. Obtaining quotes from reputable suppliers or manufacturers is the best way to get precise pricing information for nitrogen compressors.