【探花吓哭03年女孩是哪一集】最新入口

-

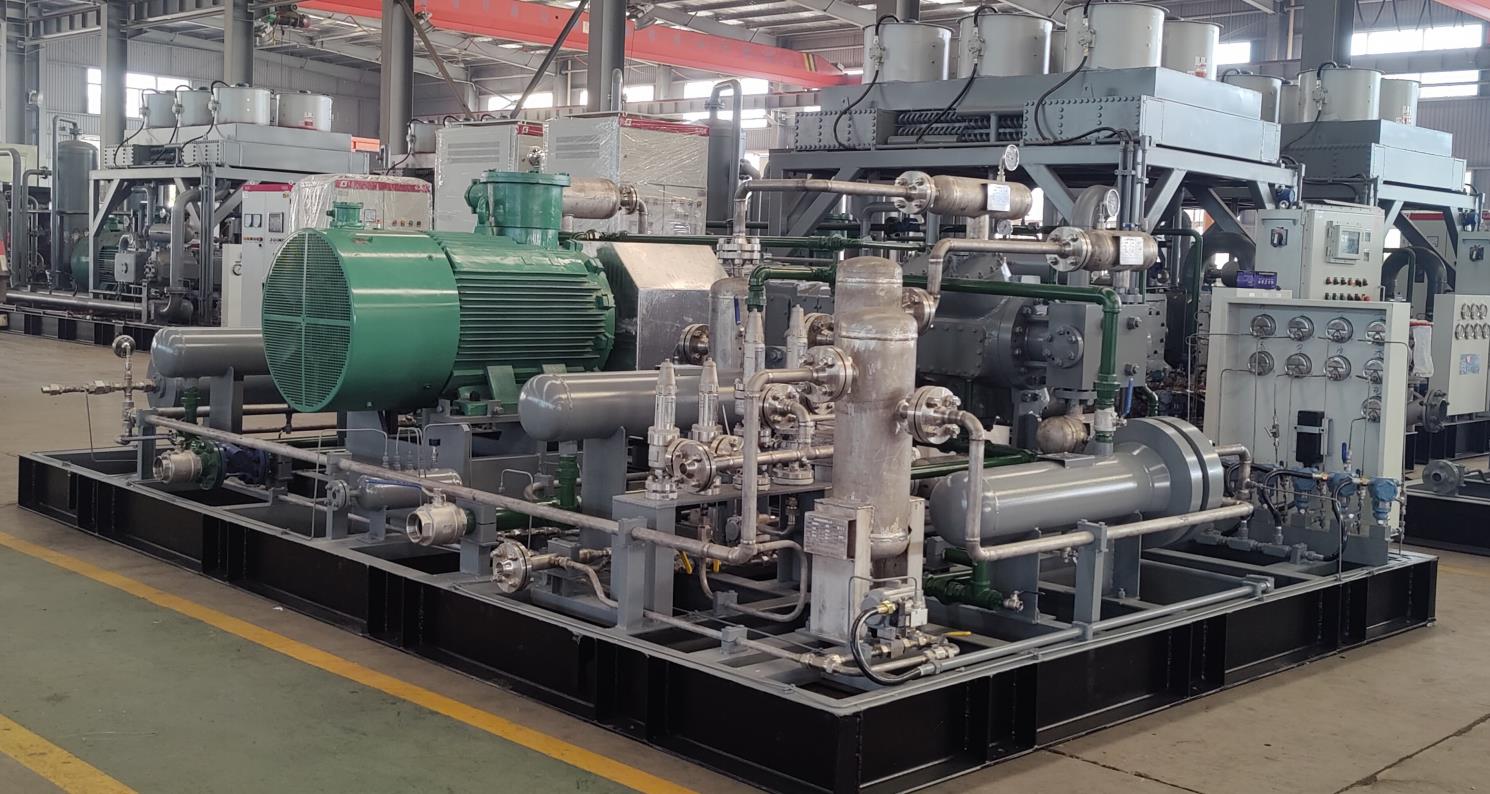

Coalbed Methane And Coalbed Methane Recovery Compressor

May 26, 2024 -

Distribution of natural gas compressor manufacturers in China, and price ranges

Jul 15, 2024 -

Some prominent butadiene compressor manufacturers in China

Jun 27, 2024 -

The working principles of chlorine gas compressor

May 24, 2024 -

Applications of butadiene compression and butadiene compressor

Jun 19, 2024 -

The Advantages And Applications Of Piston Gas Compressors

Apr 11, 2024

探花吓哭03年女孩是哪一集【乾坤易变】Apr 11, 2024

by:Anhui Shengnuo Compressor Manufacturing Co.,Ltd

Follow Us:

An industrial gas compressor is a type of compressor specifically designed for handling various gases in industrial applications. These compressors are utilized in a wide range of industries, including oil and gas, chemical processing, manufacturing, power generation, and more. They are designed to compress gases to higher pressures, enabling their transportation, processing, or utilization in different industrial processes.

Industrial gas compressors come in various types, each suited for specific gas compositions, pressure requirements, and flow rates. Some common types of industrial gas compressors include:

1. Reciprocating Compressors: Reciprocating compressors, also known as piston compressors, use reciprocating motion of pistons in cylinders to compress gases. They are commonly used for high-pressure applications and can handle a wide range of gas compositions.

2. Rotary Screw Compressors: Rotary screw compressors use two intermeshing rotors to compress gases. They are known for their continuous operation, high efficiency, and suitability for medium to high-pressure applications.

3. Centrifugal Compressors: Centrifugal compressors use centrifugal force to accelerate gases and convert kinetic energy into pressure energy. They are commonly used for large-scale, high-capacity applications and can handle higher flow rates at relatively lower compression ratios.

4. Diaphragm Compressors: Diaphragm compressors use a flexible diaphragm to compress gases. They are particularly suitable for handling toxic, corrosive, or explosive gases, making them ideal for industries with stringent safety requirements.

5. Scroll Compressors: Scroll compressors use two interleaving scrolls to compress gases. They are known for their compact size, quiet operation, and suitability for low-to-medium-pressure applications.

Industrial gas compressors play a crucial role in various industrial processes, such as gas transportation, gas storage, gas processing, chemical reactions, pneumatic tools, and more. They enable the efficient handling, storage, and utilization of gases critical to industrial operations, promoting productivity, safety, and environmental sustainability.

【探花吓哭03年女孩是哪一集】注册登录

Industrial gas compressors find a wide range of applications across various industries. Here are some common applications:

1. Gas Transmission and Distribution: Industrial gas compressors are used in gas transmission and distribution systems to compress natural gas or other gases for efficient transportation through pipelines. Compressors help maintain the required pressure levels to ensure the smooth flow of gas over long distances.

2. Petrochemical and Chemical Industries: Industrial gas compressors are utilized in petrochemical and chemical plants for processes such as gas separation, gas compression for reactions, and gas storage. They play a crucial role in supplying compressed gases for various chemical processes.

3. Oil Refining: Industrial gas compressors are employed in oil refineries for processes like hydrocracking, catalytic cracking, and hydrotreating. They assist in compressing gases used in refining operations and providing the necessary pressure for different refining processes.

4. Power Generation: Gas turbines used in power generation often require compressed air or fuel gases for combustion. Industrial gas compressors provide compressed air for turbine operation or compress fuel gases, such as natural gas or hydrogen, for combustion in gas turbine power plants.

5. Manufacturing and Industrial Processes: Industrial gas compressors are used in various manufacturing and industrial processes that require compressed air or gases. This includes pneumatic tools, air-powered machinery, spray painting, cleaning operations, and more.

6. Refrigeration and HVAC Systems: Industrial gas compressors are an integral part of refrigeration and HVAC (heating, ventilation, and air conditioning) systems. They compress refrigerant gases to generate the necessary cooling effect or to pressurize air for ventilation and conditioning.

7. Waste Water Treatment: Industrial gas compressors are used in wastewater treatment plants for aeration processes, where compressed air is introduced into wastewater to facilitate biological treatment and improve the efficiency of the treatment process.

8. Food and Beverage Industry: Industrial gas compressors are utilized in the food and beverage industry for processes like bottling, carbonation, pneumatic conveying, and packaging. They provide compressed air or specific gases required for various production and processing steps.

These are just a few examples of the wide-ranging applications of industrial gas compressors. The specific application depends on the industry, process requirements, and the type of gas being compressed. Industrial gas compressors enable the efficient handling, processing, and utilization of gases in diverse industrial sectors, contributing to productivity, quality, and operational efficiency.

【探花吓哭03年女孩是哪一集】平台地址

There are numerous specific gases that require industrial gas compressors for various applications across different industries. Here are some examples:

1. Natural Gas: Natural gas is a commonly compressed gas used for transportation, distribution, and power generation. Industrial gas compressors are employed to compress natural gas to higher pressures, facilitating its transmission through pipelines or its utilization in gas-fired power plants.

2. Hydrogen (H2): Hydrogen is used in various industries, including chemical processing, petroleum refining, electronics manufacturing, and energy production. Industrial gas compressors are utilized to compress hydrogen for storage, transportation, or specific applications that require high-pressure hydrogen.

3. Oxygen (O2): Oxygen is a vital gas used in industries such as healthcare, metal fabrication, and chemical processing. Industrial gas compressors are employed to compress oxygen for medical applications, welding and cutting processes, and other industrial uses.

4. Carbon Dioxide (CO2): Carbon dioxide finds applications in industries like food and beverage, oil and gas, and chemical processing. Industrial gas compressors are used to compress carbon dioxide for carbonation of beverages, enhanced oil recovery, gas injection processes, and other applications.

5. Nitrogen (N2): Nitrogen is widely used in industries such as food and beverage, pharmaceuticals, electronics, and chemical processing. Industrial gas compressors are utilized to compress nitrogen for packaging, inerting atmospheres, purging systems, and other nitrogen-dependent processes.

6. Compressed Air: Compressed air is a versatile utility gas used in numerous industries for pneumatic tools, machinery operation, cleaning, and other applications. Industrial gas compressors are employed to generate and compress air for these various uses.

7. Refrigerant Gases: Refrigerant gases, including R-134a, R-410A, and R-22, are used in refrigeration and air conditioning systems. Industrial gas compressors are utilized to compress these refrigerant gases, facilitating the cooling and heat transfer processes.

8. Specialty Gases: Various specialty gases, such as helium, argon, neon, krypton, and xenon, are used in industries like healthcare, electronics, lighting, and scientific research. Industrial gas compressors are employed to compress and deliver these specialty gases for specific applications.

9. Methane (CH4): Methane is the primary component of natural gas and is used as a fuel for heating, cooking, power generation, and industrial processes. Industrial gas compressors play a crucial role in compressing methane for efficient storage, transportation, and utilization.

10. Ammonia (NH3): Ammonia is widely used in the chemical industry for fertilizer production, refrigeration systems, and various manufacturing processes. Industrial gas compressors are utilized to compress and circulate ammonia in refrigeration cycles or for other specific applications.

11. Sulfur Hexafluoride (SF6): SF6 is a gas with excellent electrical insulation properties and is commonly used in high-voltage electrical equipment, such as circuit breakers and switches. Industrial gas compressors are employed to compress SF6 for storage and distribution in electrical power systems.

12. Propane (C3H8): Propane is a widely used fuel gas for heating, cooking, and fueling vehicles. Industrial gas compressors are utilized to compress propane for storage, transportation, and distribution in the propane supply chain.

13. Acetylene (C2H2): Acetylene is used in welding and cutting processes due to its high flame temperature. Industrial gas compressors are employed to compress acetylene for storage in specialized cylinders, ensuring safe handling and transportation.

14. Chlorine (Cl2): Chlorine is used in water treatment, the production of various chemicals, and the manufacturing of plastics and solvents. Industrial gas compressors are utilized to compress chlorine for storage and distribution in these applications.

15. Ethylene (C2H4): Ethylene is a crucial building block in the petrochemical industry, used for the production of plastics, synthetic fibers, and other chemicals. Industrial gas compressors are employed to compress ethylene for storage and transportation in the petrochemical supply chain.

16. Hydrofluorocarbons (HFCs): HFCs, such as R-134a and R-410A, are used as refrigerants in air conditioning and refrigeration systems. Industrial gas compressors are utilized to compress and circulate HFC refrigerants in these cooling applications.

17. Argon (Ar): Argon is used in various industrial processes, including metal fabrication, welding, and electronics manufacturing. Industrial gas compressors are employed to compress argon to the required pressure for specific applications.

18. Methanol (CH3OH): Methanol is used in industries such as chemical manufacturing, fuel production, and pharmaceuticals. Industrial gas compressors are employed to compress methanol for storage, transportation, and processing in various applications.

19. Propylene (C3H6): Propylene is a key building block in the production of plastics, synthetic fibers, and other chemicals. Industrial gas compressors are utilized to compress propylene for storage, transportation, and processing in the petrochemical industry.

20. Butane (C4H10): Butane is commonly used as a fuel gas for heating, cooking, and portable appliances. Industrial gas compressors are employed to compress butane for storage, transportation, and distribution in the fuel supply chain.

21. Ethane (C2H6): Ethane is an important component of natural gas and is used as a feedstock for ethylene production. Industrial gas compressors are utilized to compress ethane for storage, transportation, and processing in the petrochemical industry.

22. Carbon Monoxide (CO): Carbon monoxide has various industrial applications, including chemical synthesis, metallurgical processes, and fuel production. Industrial gas compressors are employed to compress carbon monoxide for storage, transportation, and utilization in these applications.

23. Hydrogen Sulfide (H2S): Hydrogen sulfide is a toxic and flammable gas that is often encountered in the oil and gas industry. Industrial gas compressors are utilized to compress and handle hydrogen sulfide for various processing and safety considerations.

24. Helium-Neon (He-Ne) Laser Gas: Helium-neon gas mixture is used in gas lasers for various applications, including scientific research, laser cutting, and barcode scanners. Industrial gas compressors are employed to compress and deliver the helium-neon gas mixture for laser systems.

25. Xenon (Xe): Xenon is used in lighting applications, including high-intensity discharge (HID) lamps and specialized lighting fixtures. Industrial gas compressors are utilized to compress xenon for storage and delivery in these lighting systems.

These are a few more examples of specific gases that require industrial gas compressors for various applications. The specific gas used depends on the industry, application, and process requirements. Industrial gas compressors enable the safe and efficient handling of these gases, ensuring their availability and reliability in a wide range of industrial processes.

【探花吓哭03年女孩是哪一集】娱乐全站

The price range of industrial gas compressors can vary significantly depending on various factors such as the type of compressor, its capacity, features, brand, and market conditions. Here are approximate price ranges for different types of industrial gas compressors:

1. Reciprocating Compressors: Reciprocating compressors are commonly used for low to medium pressure applications. The price range for reciprocating compressors can start from a few hundred dollars for small, portable units and go up to several thousand dollars for larger capacity compressors. Higher capacity reciprocating compressors or those with specialized features can cost tens of thousands of dollars or more.

2. Rotary Screw Compressors: Rotary screw compressors are widely used for medium to high-pressure applications. The price range for rotary screw compressors typically starts from a few thousand dollars for smaller capacity units and can extend to tens of thousands of dollars or more for larger capacity compressors. The specific features, such as variable speed drive or integrated dryers, can impact the price.

3. Centrifugal Compressors: Centrifugal compressors are used for high-pressure applications and large-scale industrial processes. The price range for centrifugal compressors is generally higher compared to reciprocating or rotary screw compressors. It can range from tens of thousands of dollars for smaller capacity units to several hundred thousand dollars or more for larger, high-capacity compressors.

4. Scroll Compressors: Scroll compressors are often used for smaller-scale applications and have a compact design. The price range for scroll compressors can vary from a few hundred dollars for small, portable units to several thousand dollars for larger capacity compressors.

5. Diaphragm Compressors: Diaphragm compressors are suitable for handling sensitive or hazardous gases and high-purity applications. The price range for diaphragm compressors can start from several thousand dollars for smaller units and go up to tens of thousands of dollars or more for larger capacity, specialized compressors.

Here are a few examples of industrial gas compressors along with their approximate price ranges. Please note that these prices are rough estimates and can vary based on specific configurations, capacities, and market conditions:

1. Reciprocating Compressor:

- Small portable reciprocating compressor (1-5 HP): $500 - $3,000

- Medium-sized reciprocating compressor (10-50 HP): $3,000 - $15,000

- Large capacity reciprocating compressor (50+ HP): $15,000 - $100,000+

2. Rotary Screw Compressor:

- Small rotary screw compressor (10-30 HP): $3,000 - $10,000

- Medium-sized rotary screw compressor (30-100 HP): $10,000 - $30,000

- Large capacity rotary screw compressor (100+ HP): $30,000 - $200,000+

3. Centrifugal Compressor:

- Small centrifugal compressor (50-200 HP): $20,000 - $100,000

- Medium-sized centrifugal compressor (200-500 HP): $100,000 - $500,000

- Large capacity centrifugal compressor (500+ HP): $500,000 - $2,000,000+

4. Scroll Compressor:

- Small scroll compressor (1-5 HP): $500 - $3,000

- Medium-sized scroll compressor (5-20 HP): $3,000 - $10,000

- Large capacity scroll compressor (20+ HP): $10,000 - $50,000

5. Diaphragm Compressor:

- Small diaphragm compressor (1-10 HP): $5,000 - $20,000

- Medium-sized diaphragm compressor (10-50 HP): $20,000 - $100,000

- Large capacity diaphragm compressor (50+ HP): $100,000 - $500,000+

These price ranges are provided as a general guideline and can vary significantly based on various factors such as brand, specific features, additional equipment, and customization requirements. It's always recommended to contact compressor manufacturers or suppliers for accurate pricing information based on your specific needs.

【探花吓哭03年女孩是哪一集】体育直播

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, ASC Compressor has focused on comprehensive solutions for Oilfield industry, CNG/LNG industry, Environmental protection, and Industrial compression. It has excellent quality in designing, researching, producing and manufacturing.

- Quick Link > Home > Products > Applications > News > About > Contact

-

Contact Us

- E-Mail: [email protected]

- Tel: +8618098536798/+86(0)5633698699

- Fax: +86(0)5633698699

-

Address:

No. 17 Xingye Road, Economic Development Zone, Xuanzhou District, Xuancheng City, Anhui Province, China