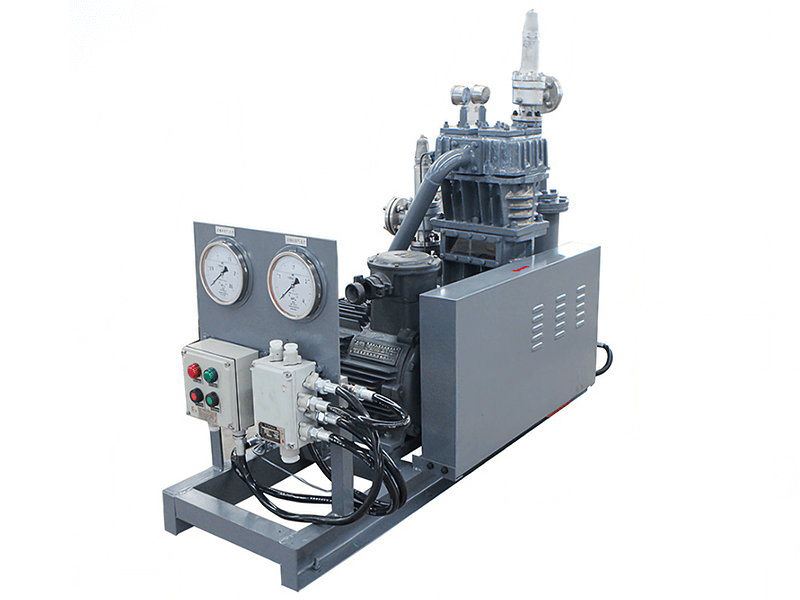

Casing gas compressor is a very common industrial compressor widely used in natural gas related industries, and there is a demand for its use in many parts of the world. We have listed the following points for reference when purchasing a casing gas compressor.

1. Gas Composition: Determine the composition of the casing gas that needs to be compressed. The gas composition can vary depending on the specific application and the well characteristics. It's essential to choose a compressor that is compatible with the composition of the casing gas to ensure proper operation and avoid any potential issues.

2. Pressure and Flow Requirements: Understand the required pressure and flow rate of the casing gas. This information will help determine the capacity and capabilities needed from the compressor. Select a compressor that can handle the desired pressure range and provide the required flow rate to meet the demands of the application.

3. Compressor Type: Different types of compressors are available for casing gas compression, such as reciprocating compressors, rotary screw compressors, and centrifugal compressors. Each type has its advantages and considerations. Evaluate the specific requirements of your application and choose the compressor type that best suits your needs in terms of efficiency, capacity, and maintenance requirements.

4. Gas Contaminants: Consider any potential contaminants present in the casing gas, such as solids, liquids, or corrosive elements. Some compressors may have features or additional equipment to handle these contaminants effectively. Ensure that the selected compressor is designed to handle the specific contaminants present in the casing gas to prevent damage or performance issues.

5. Reliability and Maintenance: Assess the reliability and maintenance requirements of the compressor. Look for a reputable manufacturer known for producing reliable and durable equipment. Consider factors such as maintenance intervals, accessibility for maintenance tasks, availability of spare parts, and the manufacturer's support and service network.

6. Safety Considerations: Casing gas compression involves handling potentially hazardous gases. Ensure that the compressor meets safety standards and regulations for the intended application. Consider features such as safety valves, pressure relief systems, and appropriate material selection to handle the gas safely.

7. Energy Efficiency: Evaluate the energy efficiency of the compressor to minimize operational costs and environmental impact. Look for compressors with energy-saving features, such as variable speed drives, efficient motor systems, or optimization controls, to reduce energy consumption during operation.

8. Budget and Total Cost of Ownership: Consider the initial purchase cost of the compressor as well as the long-term costs associated with maintenance, energy consumption, and potential downtime. Assess the total cost of ownership over the compressor's lifespan to make an informed decision based on your budget and cost considerations.

9. Operating Conditions: Evaluate the specific operating conditions of your application. Factors such as ambient temperature, altitude, and environmental conditions can impact the performance and selection of the compressor. Ensure that the chosen compressor is designed to operate effectively under the anticipated conditions.

10. Noise and Vibration Levels: Consider the noise and vibration levels produced by the compressor. If noise or vibration is a concern, look for compressors that are designed with sound insulation or vibration dampening features. This is particularly important if the compressor will be located near residential areas or sensitive equipment.

11. Size and Space Constraints: Assess the available space for installing the compressor. Determine the physical dimensions and weight of the compressor and ensure that it can be accommodated in the designated area. Additionally, consider access requirements for maintenance and service tasks.

12. Compliance and Certification: Verify that the compressor meets relevant industry standards, certifications, and safety regulations. Look for certifications such as ISO, API, or other applicable standards to ensure that the compressor meets quality and performance requirements.

13. Control and Monitoring Systems: Evaluate the control and monitoring systems provided with the compressor. Advanced features such as remote monitoring, diagnostic capabilities, and integration with automation systems can enhance operational efficiency and facilitate maintenance and troubleshooting.

14. Service and Support: Consider the availability of service and support from the manufacturer or supplier. Ensure that you have access to technical assistance, spare parts, and maintenance services to support the ongoing operation of the compressor.

15. Future Expansion and Flexibility: Anticipate any future expansion or changes in your casing gas compression needs. Choose a compressor that offers flexibility and scalability, allowing for potential capacity upgrades or modifications to meet future requirements.

16. Lifecycle Cost Analysis: Conduct a lifecycle cost analysis to evaluate the long-term costs associated with the compressor. Consider factors such as energy efficiency, maintenance requirements, expected lifespan, and potential downtime costs. This analysis will help you make an informed decision by considering the overall economic impact of the compressor.

By considering these factors and conducting thorough research, you can choose a casing gas compressor that is well-suited to your specific requirements, ensuring reliable and efficient operation in your application. It is advisable to consult with manufacturers, suppliers, or industry experts to get guidance and assistance in selecting the most suitable compressor for your casing gas compression needs.

About price

Please note that these prices are approximate and can vary based on factors such as compressor capacity, specifications, brand, and market conditions. It's essential to contact manufacturers or suppliers for accurate and up-to-date pricing information. Here is a rough estimate of the price ranges for different types of casing gas compressors:

1. Reciprocating (Piston) Compressor:

- Small to Medium Capacity: $5,000 to $20,000

- Medium to Large Capacity: $20,000 to $100,000+

2. Rotary Screw Compressor:

- Small to Medium Capacity: $10,000 to $30,000

- Medium to Large Capacity: $30,000 to $200,000+

3. Centrifugal Compressor:

- Medium to Large Capacity: $100,000 to $500,000+

- Large Capacity Industrial Applications: $500,000 to several million dollars

4. Diaphragm Compressor:

- Small to Medium Capacity: $10,000 to $30,000

- Medium to Large Capacity: $30,000 to $100,000+

These price ranges are provided as a general guideline and can vary significantly depending on the specific requirements, customization, additional features, and market factors. It's always recommended to obtain detailed quotes and pricing information from manufacturers or suppliers to get accurate pricing for the casing gas compressor type and specifications you need.

Casing gas compressor sales service

Our company specializes in the design, manufacturing, and sales of industrial gas compressors, catering to the specific needs of the oil and gas industry and various other applications. With years of experience and a strong reputation in the market, we have established ourselves as a trusted provider of high-quality industrial gas compressors.

Sales Process:

We have a dedicated sales team that works closely with customers to understand their requirements and provide tailored solutions. Our sales representatives are knowledgeable about our product offerings and can guide customers in choosing the right casing gas compressor for their applications. They provide detailed information, technical specifications, and assistance throughout the sales process, ensuring a smooth and informed purchasing experience.

Manufacturing Capabilities:

Our manufacturing facilities are equipped with state-of-the-art machinery and employ skilled engineers and technicians. We adhere to strict quality control measures and follow industry standards to ensure that our casing gas compressors meet the highest standards of performance, reliability, and safety. We utilize advanced manufacturing techniques and materials to produce robust and efficient compressors that can endure demanding operating conditions.

Price Advantages:

We understand the importance of competitive pricing in today's market. While the specific pricing of our casing gas compressors can vary based on various factors, we strive to offer cost-effective solutions to our customers. Here are some price advantages we provide:

1. Competitive Pricing: We aim to provide pricing that is competitive within the market, offering value for the quality and performance of our casing gas compressors.

2. Customization options: We offer customizable features and configurations, allowing customers to select components and specifications that align with their specific needs and budget. This flexibility helps optimize the pricing based on individual requirements.

3. Total Cost of Ownership: Our casing gas compressors are designed with energy efficiency and durability in mind. By focusing on efficiency, we help customers reduce operating costs and minimize long-term expenses associated with maintenance, energy consumption, and downtime.

4. After-Sales Support: We provide comprehensive after-sales support, including warranty coverage, technical assistance, and access to spare parts. Our commitment to customer satisfaction ensures that our customers receive reliable and efficient support throughout the lifespan of their casing gas compressors.

By combining our expertise in manufacturing, customer-centric sales approach, and competitive pricing strategies, we strive to deliver high-quality casing gas compressors that meet the unique requirements of our customers while offering favorable pricing advantages.