A natural gas booster compressor, also known as a gas booster or gas compression booster, is a type of compressor specifically designed to increase the pressure of natural gas in a pipeline or system. It is commonly used in various applications where the natural gas pressure needs to be elevated to meet specific operational requirements.

Here are some key features and functions of a natural gas booster compressor:

1. Pressure Boosting: The primary function of a natural gas booster compressor is to increase the pressure of the incoming natural gas. It takes low-pressure gas from the source or pipeline and compresses it to a higher pressure for further transportation or utilization.

2. Efficiency and Performance: Natural gas booster compressors are designed to operate efficiently and deliver reliable performance. They are engineered to handle the specific characteristics of natural gas, including its composition and varying flow rates, while maintaining optimal compression efficiency.

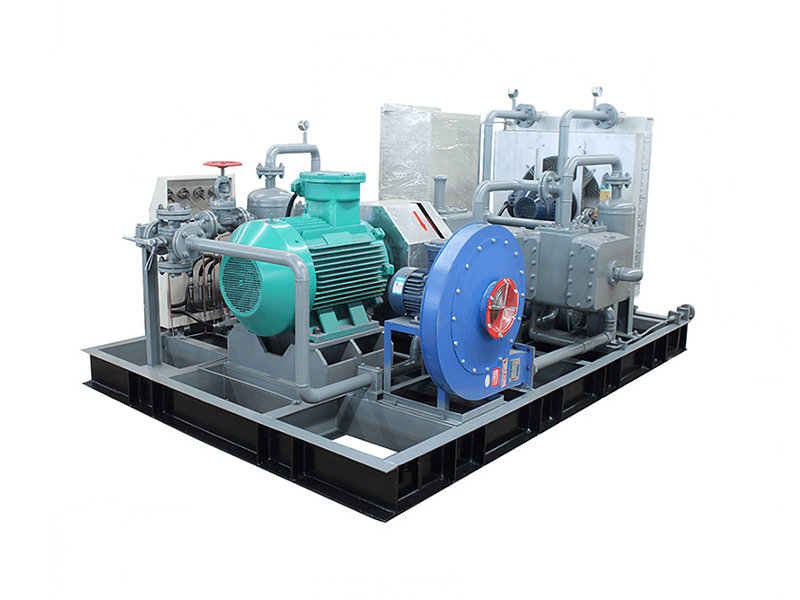

3. Compact Design: Booster compressors are typically compact in size and designed for easy installation. They often come as skid-mounted units or packaged systems, which include the compressor, motor or engine, controls, and necessary safety features.

4. Safety Considerations: Natural gas booster compressors incorporate safety features to ensure proper operation and mitigate potential risks. These may include pressure relief valves, temperature sensors, automatic shutdown mechanisms, and other safety protocols to protect against overpressure or abnormal operating conditions.

5. Control and Monitoring: Booster compressors are equipped with control systems that allow operators to monitor and adjust the compression process. These systems may include instrumentation, pressure and temperature sensors, and programmable logic controllers (PLCs) for precise control and monitoring of the compressor's performance.

6. Compatibility: Natural gas booster compressors are designed to handle the specific requirements and characteristics of natural gas, including its composition, temperature, and potential impurities. They are constructed with materials and components that are compatible with natural gas and can withstand its corrosive and reactive properties.

7. Types of Natural Gas Booster Compressors: Natural gas booster compressors can be categorized into different types based on their operating principles, including:

- Reciprocating Compressors: These compressors use a piston-cylinder arrangement to compress the natural gas. They are known for their high compression ratios and are suitable for higher-pressure applications.

- Rotary Screw Compressors: Rotary screw compressors use two interlocking helical rotors to compress the gas. They provide continuous and smooth compression, making them suitable for various flow rates and pressure ranges.

- Centrifugal Compressors: Centrifugal compressors utilize high-speed rotating impellers to accelerate and compress the gas. They are commonly used for large-scale natural gas compression applications and can handle higher flow rates.

8. Applications of Natural Gas Booster Compressors: Natural gas booster compressors find application in various industries and processes, including:

- Natural Gas Pipeline Transmission: Booster compressors are used to increase the pressure of natural gas in long-distance transmission pipelines, ensuring efficient and reliable transport of gas over large distances.

- Gas Gathering Systems: In gas gathering systems, where natural gas is collected from multiple wells or sources, booster compressors help maintain the required pressure for efficient flow and transport to processing facilities.

- Natural Gas Fueling Stations: Booster compressors are utilized in natural gas fueling stations to increase the pressure of natural gas for refueling vehicles powered by compressed natural gas (CNG).

- Industrial Processes: Natural gas booster compressors are employed in various industrial processes where elevated gas pressure is required for specific applications, such as in manufacturing, petrochemicals, and power generation.

9. Cost of Natural Gas Booster Compressors: The cost of a natural gas booster compressor can vary depending on several factors, including capacity, pressure requirements, features, and the manufacturer or supplier. Generally, the price range for natural gas booster compressors can start from several thousand dollars for smaller-capacity units and go up to several hundred thousand dollars or more for larger, high-capacity systems.

Here are some price examples for natural gas booster compressors. Please note that these prices are approximate and can vary depending on various factors such as capacity, brand, features, and market conditions. Prices are in USD.

1. Reciprocating Compressor:

- Small-scale reciprocating compressor: $5,000 - $20,000

- Industrial-grade reciprocating compressor: $20,000 - $100,000 or more

2. Rotary Screw Compressor:

- Small to medium-sized rotary screw compressor: $10,000 - $30,000

- Large-sized rotary screw compressor: $30,000 - $200,000 or more

3. Centrifugal Compressor:

- Small-scale centrifugal compressor: $30,000 - $100,000

- Industrial-grade centrifugal compressor: $100,000 - $1,000,000 or more

It's important to consult with reputable compressor manufacturers or suppliers to obtain accurate pricing information based on your specific requirements and to ensure the selection of the appropriate natural gas booster compressor for your application.