Natural gas recovery and gathering refer to the processes involved in extracting and collecting natural gas from underground reservoirs and transporting it to processing facilities or distribution systems. It is a crucial stage in the overall natural gas production and supply chain. Here's an overview of these processes:

1. Natural Gas Recovery:

- Drilling: Natural gas recovery begins with drilling wells into underground reservoirs that contain trapped natural gas. Wells can be drilled vertically or horizontally, depending on the geological characteristics of the reservoir.

- Well Completion: Once the well is drilled, it is completed with cement casing and tubing to ensure the integrity of the wellbore. Various techniques, such as hydraulic fracturing (fracking), may be employed to enhance gas recovery from unconventional reservoirs.

- Reservoir Pressure: In some cases, the natural pressure within the reservoir is sufficient to push the gas to the surface (known as natural flow). However, in most cases, additional measures are required to extract the gas effectively.

2. Natural Gas Gathering:

- Wellhead Equipment: At the wellhead, gathering equipment is installed to control and regulate the flow of natural gas. This equipment may include valves, separators, and meters to measure the gas flow rate and composition.

- Gathering Pipelines: Once the gas is extracted at the wellhead, it is transported through gathering pipelines. These pipelines connect multiple wells in the same field and transport the gas to a central collection point or a processing facility.

- Compression: Along the gathering pipelines, compressor stations are strategically placed to maintain the pressure and ensure the continuous flow of gas. Compressors increase the pressure of the gas to overcome frictional losses and maintain the desired flow rate.

- Measurement and Control: Throughout the gathering process, gas flow rates, pressures, and other parameters are measured and monitored to ensure efficient operations, safety, and accurate accounting of the produced gas.

3. Gas Processing: Depending on the composition of the extracted natural gas, processing facilities may be required to remove impurities, such as water, sulfur compounds, and other contaminants. This processing typically takes place at dedicated plants where the gas is treated and conditioned to meet the required quality standards.

4. Transmission and Distribution: After processing, the natural gas is typically transported through transmission pipelines over long distances to reach distribution points or end-users. From there, it is further distributed through local distribution networks to residential, commercial, and industrial consumers.

5. Storage: Natural gas can also be stored during periods of low demand or excess supply. Underground storage facilities, such as depleted gas reservoirs or salt caverns, are used to store natural gas. This enables flexibility in meeting fluctuating demand and helps maintain supply reliability.

6. Midstream Infrastructure: Midstream infrastructure refers to the network of pipelines, compressor stations, storage facilities, and other components that facilitate the transportation and storage of natural gas. It includes gathering pipelines, transmission pipelines, and associated facilities that connect production areas to processing plants, distribution systems, and export terminals.

It's worth noting that the specific processes and infrastructure for natural gas recovery and gathering can vary depending on regional and operational factors. Local regulations, geological conditions, and market dynamics influence the design and operation of natural gas recovery and gathering systems.

Overall, natural gas recovery and gathering play a vital role in harnessing natural gas resources, ensuring their efficient transportation, and delivering them to consumers. These processes require careful planning, adherence to safety and environmental standards, and ongoing technological advancements to optimize operations and minimize environmental impact.

Natural gas recovery methods

Natural gas recovery methods vary depending on the type of reservoir and its geological characteristics. Here are some common techniques used to recover natural gas:

1. Conventional Gas Recovery:

- Natural Flow: In some cases, the pressure within the reservoir is sufficient to allow the gas to flow naturally to the surface. Wells are drilled, and the gas is produced without the need for additional stimulation or artificial lift techniques.

- Artificial Lift: When reservoir pressure is insufficient for natural flow, artificial lift methods are employed. This involves using equipment such as pumps, gas lift systems, or plunger lift systems to lift the gas to the surface.

2. Unconventional Gas Recovery:

- Hydraulic Fracturing (Fracking): In unconventional gas reservoirs, such as shale, tight sandstone, or coalbed methane, hydraulic fracturing is commonly used. This process involves drilling horizontal wells and injecting fluids under high pressure to create fractures in the reservoir rock, which releases trapped gas and improves its flow characteristics.

- Horizontal Drilling: Unconventional gas recovery often involves drilling horizontal wells that intersect the target reservoir. This technique maximizes contact with the gas-bearing formation, enhancing gas recovery rates.

- Multi-Stage Fracturing: In combination with horizontal drilling, multi-stage fracturing is employed to create multiple fractures along the wellbore. This technique involves isolating sections of the well and sequentially fracturing each segment to enhance the connectivity between the reservoir and the wellbore.

3. Enhanced Gas Recovery:

- Gas Injection: In some cases, gases such as carbon dioxide (CO2) or nitrogen (N2) can be injected into the reservoir to enhance gas recovery. This method can help maintain reservoir pressure, displace the natural gas, or alter the gas properties to improve flow.

- Gas Cycling: Gas cycling involves injecting produced gas back into the reservoir to maintain reservoir pressure and improve gas recovery. This technique can be applied when the reservoir exhibits favorable characteristics for gas storage and subsequent production.

4. Enhanced Oil Recovery (EOR):

- If the target reservoir contains both oil and natural gas, enhanced oil recovery methods can be employed. EOR techniques such as gas injection (CO2 or natural gas) or chemical flooding can be used to increase oil production. It is important to note that these methods can also result in the recovery of associated natural gas.

5. Coalbed Methane Recovery:

- Degasification: In coal seams, methane gas is trapped within the coal matrix. Degasification techniques involve drilling wells into coal seams and extracting the methane gas by reducing the pressure within the coal seam. This is typically achieved by pumping out groundwater or using other methods to lower the pressure and release the trapped methane.

6. Offshore Gas Recovery:

- Offshore Platforms: In offshore gas fields, production platforms are installed to extract natural gas from beneath the seabed. Wells are drilled from the platforms to access the gas reservoirs. Subsea completion techniques may also be used, where wells are drilled and completed on the seafloor, and the gas is transported through underwater pipelines to the production platforms.

7. Tight Gas Recovery:

- Stimulation Techniques: Tight gas reservoirs have low permeability, making gas recovery challenging. Stimulation techniques such as hydraulic fracturing, acidizing, or other forms of reservoir stimulation are employed to enhance gas flow. These techniques involve creating fractures or channels in the reservoir rock to improve the gas's ability to flow to the wellbore.

8. Coal Gasification:

- Gasification: Coal gasification is a process that converts coal into synthetic gas (syngas), which primarily consists of carbon monoxide (CO) and hydrogen (H2). Syngas can be further processed to separate and recover methane for use as natural gas. This method is commonly used when coal reserves are abundant, and natural gas availability is limited.

9. Underground Coal Gasification (UCG):

- UCG involves converting coal in situ into a mixture of gases, including methane, by partial combustion or gasification underground. The gases produced can be recovered and utilized as natural gas. UCG is considered an unconventional method and is still under development for commercial-scale applications.

10. Gas Hydrate Recovery:

- Gas hydrates are ice-like structures that contain large amounts of methane trapped within them. Recovery techniques for gas hydrates are still in the experimental stage. Methods being explored include depressurization, thermal stimulation, and chemical methods to release and collect the methane from hydrate formations.

It's important to note that the selection of a specific natural gas recovery method depends on factors such as reservoir characteristics, economic viability, technological feasibility, and environmental considerations. Each method has its own advantages, challenges, and potential impacts, and their suitability varies depending on the specific conditions of the gas reservoir.

Natural gas gathering methods

Natural gas gathering refers to the collection and transportation of natural gas from multiple wells or production sites to a central point, where further processing or distribution takes place. Here are some common methods used in natural gas gathering:

1. Gathering Pipelines:

- Gathering pipelines are a network of pipelines that connect individual wells or production sites to a central collection point, such as a processing facility or a transmission pipeline. These pipelines transport the extracted natural gas from multiple sources over relatively short distances.

- Gathering pipelines are typically smaller in diameter compared to transmission pipelines, ranging from a few inches to a foot or more, depending on the volume of gas being transported.

- The pipelines are made of steel or other materials suitable for transporting natural gas, and they are often buried underground for protection and to minimize environmental impact.

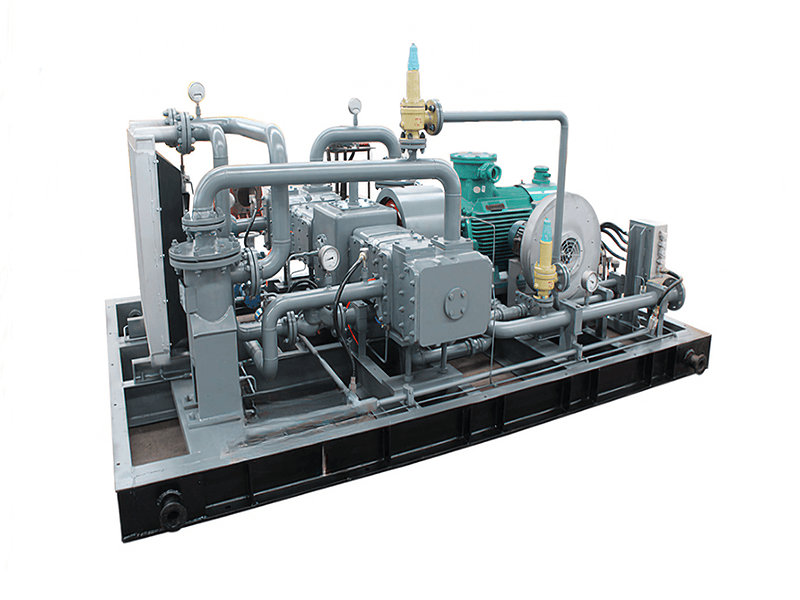

2. Compressor Stations:

- Compressor stations are strategically located along the gathering pipeline network to maintain and boost the pressure of the natural gas as it flows through the system.

- Compressors are used to overcome frictional losses and maintain the desired flow rate. They increase the pressure of the gas, ensuring its continuous movement along the pipeline.

- Compressor stations typically include equipment such as natural gas compressors, filters, separators, and control systems to monitor and regulate the gas flow and pressure.

3. Metering and Measurement:

- Metering and measurement stations are installed at various points along the gathering pipeline system to accurately measure the volume, pressure, and composition of the natural gas being transported.

- These stations help in commercial accounting, ensuring accurate billing and allocation of the gas among different producers or customers.

- Metering and measurement stations may also include flow control valves and instrumentation to monitor and control the gas flow.

4. Pigging:

- Pigging refers to the practice of using devices called "pigs" to clean, inspect, or maintain the integrity of the gathering pipelines.

- Cleaning pigs are inserted into the pipeline and propelled by the flowing gas or by an external power source. They remove debris, scale, or other deposits that can accumulate and hinder gas flow or corrode the pipeline.

- Inspection pigs are equipped with sensors and instruments to assess the condition of the pipeline, detect anomalies, and identify potential integrity issues.

- Pigging helps ensure the efficient operation and integrity of the gathering pipeline system.

5. Valves and Regulation:

- Gathering pipelines are equipped with various valves to control the flow of natural gas, isolate sections of the pipeline for maintenance or repairs, and regulate pressure.

- Pressure regulation systems, such as pressure control valves or regulators, maintain the desired pressure levels within the gathering pipeline to ensure safe and efficient operation.

6. SCADA Systems:

- Supervisory Control and Data Acquisition (SCADA) systems are used to monitor and control the gathering pipeline network remotely.

- SCADA systems collect real-time data from various sensors and instruments along the pipeline, enabling operators to monitor the gas flow, pressure, temperature, and other critical parameters.

- SCADA systems also allow operators to remotely control valves, compressors, and other equipment, ensuring smooth and reliable operation of the gathering system.

These methods work together to efficiently collect natural gas from multiple wells or production sites and transport it to the desired destination, such as a processing facility for further treatment or a transmission pipeline for distribution. Safety measures, maintenance programs, and adherence to regulatory guidelines are essential to ensure the integrity, reliability, and environmental performance of the natural gas gathering system.