There are several types of mixed gas compressors available, each designed to handle specific gas mixtures and meet varying requirements. Here are some common types of mixed gas compressors:

1. Reciprocating Compressors: Reciprocating compressors, also known as piston compressors, are widely used for compressing mixed gases. They use a reciprocating motion of a piston within a cylinder to compress the gas mixture. Reciprocating compressors are known for their high efficiency, reliability, and ability to handle a wide range of gas compositions.

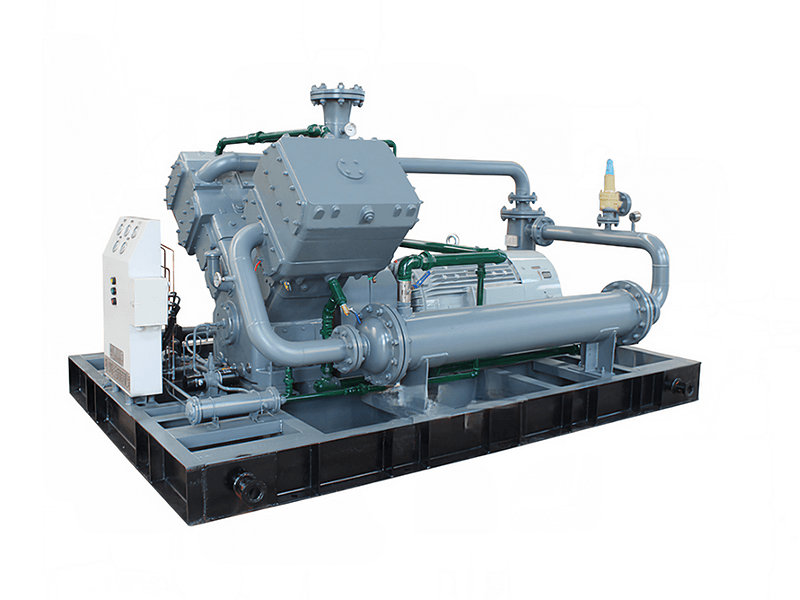

2. Rotary Screw Compressors: Rotary screw compressors are another type of mixed gas compressor commonly used in industrial applications. They utilize two interlocking helical screws to compress the gas mixture. Rotary screw compressors offer continuous, pulsation-free operation and are suitable for handling a variety of gas mixtures.

3. Centrifugal Compressors: Centrifugal compressors are used for compressing large volumes of gas mixtures at high flow rates. They rely on centrifugal force to accelerate and compress the gas mixture. Centrifugal compressors are known for their compact design, high capacity, and suitability for handling gases with low molecular weights.

4. Diaphragm Compressors: Diaphragm compressors use a flexible diaphragm to compress the gas mixture. The diaphragm acts as a barrier between the gas and the compressor components, ensuring gas purity and preventing contamination. Diaphragm compressors are often used for handling corrosive or hazardous gas mixtures and in applications where gas leakage must be minimized.

5. Scroll Compressors: Scroll compressors are commonly used in smaller-scale applications or where lower flow rates are required. They utilize two interlocking spiral scrolls to compress the gas mixture. Scroll compressors offer smooth, quiet operation, and are suitable for handling gas mixtures in HVAC systems, refrigeration, and smaller industrial processes.

6. Liquid Ring Compressors: Liquid ring compressors use a ring of liquid (typically water) to create a seal and compress the gas mixture. They are often used for handling wet or saturated gas mixtures and in applications that require high gas purity. Liquid ring compressors are commonly found in industries such as chemical processing, petroleum refining, and environmental applications.

7. Axial Compressors: Axial compressors are specifically designed for compressing gas mixtures where the flow is primarily in the axial direction. They consist of a series of rotating blades and stationary stator vanes that accelerate and compress the gas mixture. Axial compressors are used in applications such as gas turbines, jet engines, and certain industrial processes.

Comparison of the different types of mixed gas compressors

1. Reciprocating Compressors:

- Pros: High efficiency, reliable, suitable for a wide range of gas compositions, can handle high pressures, and available in various sizes and capacities.

- Cons: Higher maintenance requirements compared to some other types, can generate more noise and vibration.

2. Rotary Screw Compressors:

- Pros: Continuous, pulsation-free operation, compact design, efficient, suitable for handling a variety of gas mixtures, and available in various sizes and capacities.

- Cons: Limited to moderate compression ratios, may have higher initial costs compared to reciprocating compressors.

3. Centrifugal Compressors:

- Pros: High capacity, suitable for high flow rates, compact design, lower vibration and noise levels compared to reciprocating compressors, and can handle gases with low molecular weights.

- Cons: Limited to moderate compression ratios, higher initial costs, may require more complex control systems.

4. Diaphragm Compressors:

- Pros: Suitable for handling corrosive or hazardous gas mixtures, high gas purity, minimal gas leakage, and can provide pulsation-free compression.

- Cons: Lower flow rates compared to some other types, may have limitations on pressure and capacity.

5. Scroll Compressors:

- Pros: Smooth and quiet operation, compact design, suitable for HVAC and smaller-scale applications, reliable, and relatively low maintenance.

- Cons: Limited to lower flow rates, may have limitations on pressure and capacity, not suitable for handling high molecular weight gases.

6. Liquid Ring Compressors:

- Pros: Suitable for handling wet or saturated gas mixtures, high gas purity, can handle a wide range of pressures, and can tolerate liquid carryover.

- Cons: Lower efficiency compared to some other types, require a constant source of sealing liquid, higher maintenance requirements.

7. Axial Compressors:

- Pros: High flow rates, suitable for applications with primarily axial gas flow, efficient, and commonly used in gas turbines and jet engines.

- Cons: Limited to specific applications, higher costs, complex design and maintenance requirements, not suitable for all gas mixtures.

Price ranges of mixed gas compressors

The price ranges of mixed gas compressors can vary depending on several factors, including the type of compressor, its capacity, design features, and the specific application requirements. Here's a general overview of the price ranges for different types of mixed gas compressors:

1. Reciprocating Compressors: The price range for reciprocating compressors can vary widely depending on factors such as capacity, materials of construction, and additional features. Smaller reciprocating compressors with lower capacities can range from a few hundred to several thousand dollars. Larger reciprocating compressors with higher capacities can range from several thousand to tens of thousands of dollars.

2. Rotary Screw Compressors: The price range for rotary screw compressors is generally higher compared to reciprocating compressors. Smaller rotary screw compressors with lower capacities typically start in the range of a few thousand dollars and can go up to tens of thousands of dollars. Larger rotary screw compressors with higher capacities can range from tens of thousands to several hundred thousand dollars.

3. Centrifugal Compressors: Centrifugal compressors are typically more expensive compared to reciprocating and rotary screw compressors. The price range for centrifugal compressors can start from tens of thousands of dollars for smaller units and go up to several million dollars for larger, high-capacity compressors.

4. Diaphragm Compressors: Diaphragm compressors often fall in the mid to high price range due to their specialized design and materials. The price range for diaphragm compressors can start from a few thousand dollars for smaller units and go up to tens of thousands of dollars for larger, high-capacity compressors.

5. Scroll Compressors: Scroll compressors generally have a lower price range compared to other types of compressors. The price range for scroll compressors can start from a few hundred dollars for smaller units and go up to a few thousand dollars for larger, higher-capacity compressors.

6. Liquid Ring Compressors: Liquid ring compressors tend to have a higher price range compared to some other types of compressors due to their specialized design and construction. The price range for liquid ring compressors can start from several thousand dollars for smaller units and go up to hundreds of thousands of dollars for larger, high-capacity compressors.

7. Axial Compressors: Axial compressors are typically the most expensive type of mixed gas compressors. The price range for axial compressors can start from tens of thousands of dollars for smaller units and can reach several million dollars for larger, high-capacity compressors used in industrial applications.

It's important to note that these price ranges are approximate and can vary significantly based on factors such as the compressor's specifications, brand, additional features, and market conditions. It's recommended to consult with compressor manufacturers or distributors to get accurate pricing information for specific compressor models and configurations.