【亲吻刺激战场视频大全免费观看】最新入口

-

Price range of Natural Gas Compressors with different cooling methods

Jun 16, 2024 -

Components and maintenance of a boil-off gas compressor

Jun 23, 2024 -

Applications and industries where chlorine compression is needed

May 06, 2024 -

Some prominent butadiene compressor manufacturers in China

Jun 27, 2024 -

Manufacturers of natural gas compressors in China and other countries

Apr 16, 2024 -

Types of gases found in oil fields and features of oil field compressors

Jul 13, 2024

亲吻刺激战场视频大全免费观看【乾坤易变】Jun 13, 2024

by:Anhui Shengnuo Compressor Manufacturing Co.,Ltd

Follow Us:

A natural gas booster is a type of compressor used specifically for increasing the pressure of natural gas in a pipeline or gas distribution system. It is designed to handle the specific requirements and characteristics of natural gas, ensuring efficient and reliable operation.

The primary function of a natural gas booster is to boost the pressure of the gas to overcome frictional losses, maintain flow rates, and meet the pressure requirements of downstream processes or end-users. Boosting the pressure of natural gas is necessary for efficient transportation, distribution, or utilization of the gas.

Here are some key features and applications of natural gas boosters:

1. Pressure Increase: Natural gas boosters are designed to provide a significant pressure increase to the gas passing through the system. They can raise the pressure from the initial inlet pressure to a higher discharge pressure, as required by the specific application or pipeline.

2. Pipeline Transmission: Natural gas boosters are commonly used in long-distance pipeline transmission systems. They help maintain the required pressure levels along the pipeline to ensure the gas reaches its destination reliably and efficiently.

3. Gas Distribution: In gas distribution networks, natural gas boosters are used to increase the pressure of the gas to meet the demand of residential, commercial, or industrial consumers. Boosters are strategically placed at specific points in the distribution system to ensure adequate pressure levels for safe and efficient gas supply.

4. Gas Storage: Natural gas boosters are employed in gas storage facilities to increase the pressure of the gas during injection into storage reservoirs or caverns. This enables efficient storage capacity utilization and facilitates later withdrawal of the gas for consumption.

5. Gas Compression Stations: Natural gas boosters are often installed at compression stations along the gas transmission network to maintain or increase the pressure of the gas as it flows through the pipeline. These stations help overcome pressure drops caused by distance, elevation changes, or other factors.

6. Gas Fueling Stations: In natural gas vehicle (NGV) fueling stations, natural gas boosters are used to increase the pressure of the gas to the required level for fueling NGVs. This ensures efficient and rapid refueling of natural gas-powered vehicles.

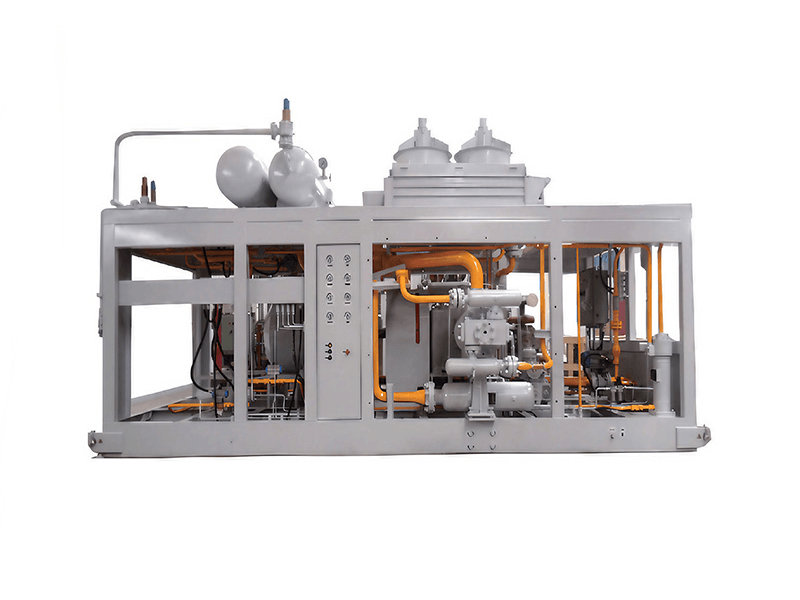

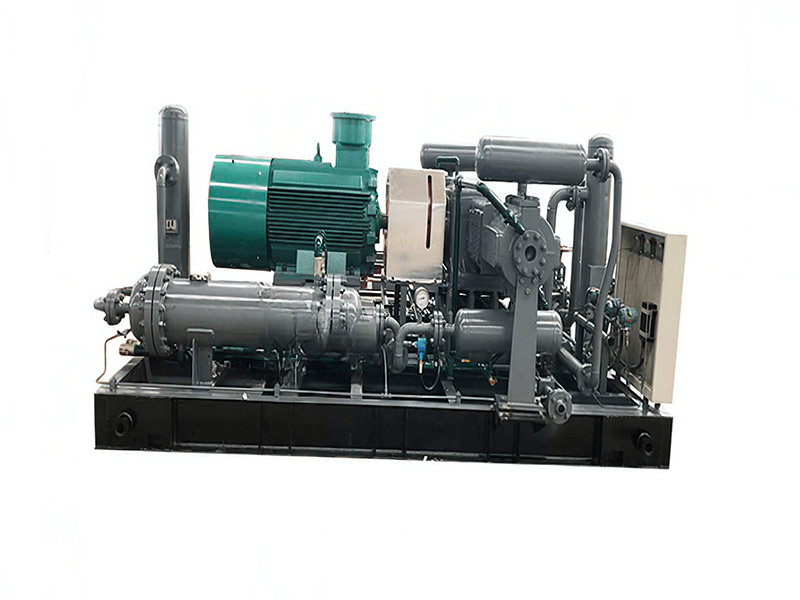

Natural gas boosters are typically driven by electric motors or gas engines, and they can be configured as reciprocating compressors or centrifugal compressors, depending on the specific application and requirements.

The use of natural gas boosters helps optimize the natural gas distribution system, maintain efficient flow rates, and ensure the reliable supply of natural gas to various consumers and industries.

The "natural gas booster" and "natural gas compressor" are often used interchangeably, as both refer to equipment designed to increase the pressure of natural gas. However, it's important to note that there can be some subtle differences in their specific applications and operating characteristics.

In general, a natural gas booster is a type of natural gas compressor that is specifically focused on increasing the pressure of natural gas within a system. It is typically used to boost the pressure at specific points along a pipeline or within a gas distribution network to overcome pressure drops, maintain flow rates, or meet the pressure requirements of downstream processes or end-users.

On the other hand, the "natural gas compressor" is a more generic term that can encompass a wider range of compressors used in the natural gas industry. It can include not only boosters but also other types of compressors used for various purposes, such as gas gathering, gas processing, storage, or transportation.

In essence, all natural gas boosters are natural gas compressors, but not all natural gas compressors are boosters. Natural gas compressors can be classified into different types based on their specific applications, such as associated gas compressors, injection gas compressors, process gas compressors, or transmission gas compressors.

The key distinction between a natural gas booster and other types of natural gas compressors lies in their primary purpose, which is to boost the pressure of the gas. Boosters typically operate at a relatively lower compression ratio and are focused on maintaining or increasing the pressure of the gas at a specific point in the system.

Other types of natural gas compressors, such as transmission compressors or process compressors, may be designed to handle a wider range of compression ratios and perform additional functions like gas treatment, dehydration, or large-scale gas transmission over long distances.

In summary, while the "natural gas booster" and "natural gas compressor" are often used interchangeably, a natural gas booster is a specific type of natural gas compressor that is primarily focused on increasing the pressure of the gas at a specific point in the system.

【亲吻刺激战场视频大全免费观看】注册登录

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, ASC Compressor has focused on comprehensive solutions for Oilfield industry, CNG/LNG industry, Environmental protection, and Industrial compression. It has excellent quality in designing, researching, producing and manufacturing.

- Quick Link > Home > Products > Applications > News > About > Contact

-

Contact Us

- E-Mail: [email protected]

- Tel: +8618098536798/+86(0)5633698699

- Fax: +86(0)5633698699

-

Address:

No. 17 Xingye Road, Economic Development Zone, Xuanzhou District, Xuancheng City, Anhui Province, China