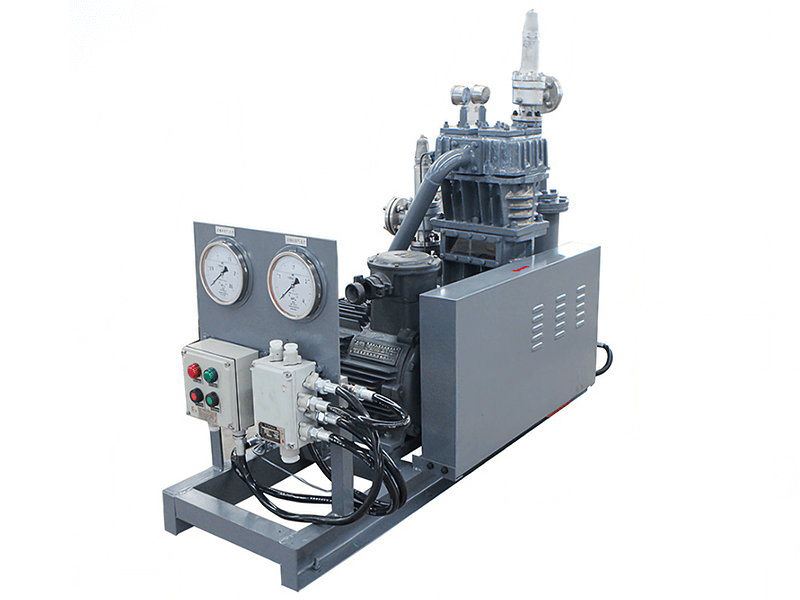

A reciprocating piston chlorine compressor is a specific type of compressor designed for handling chlorine gas. Here are some key features and characteristics commonly associated with reciprocating piston chlorine compressors:

1. Piston Design: Reciprocating piston compressors use one or more pistons driven by a crankshaft to compress the gas. The piston(s) move back and forth within a cylinder, creating compression and discharge of the chlorine gas.

2. Corrosion-Resistant Materials: Chlorine gas is highly corrosive, so reciprocating piston chlorine compressors are typically constructed using materials that are resistant to chlorine's corrosive effects. Common materials include stainless steel, nickel alloys, or other corrosion-resistant materials.

3. Chlorine-Resistant Seals: Specialized seals are used to prevent leakage of chlorine gas during the compression process. These seals are designed to be resistant to chlorine and are crucial for maintaining the integrity of the compressor system.

4. Safety Devices: Reciprocating piston chlorine compressors incorporate various safety devices to ensure safe operation. These can include pressure relief valves, rupture discs, gas leak detection systems, and emergency shutdown systems. These safety features are essential for preventing overpressure situations and minimizing the risk of chlorine gas leaks.

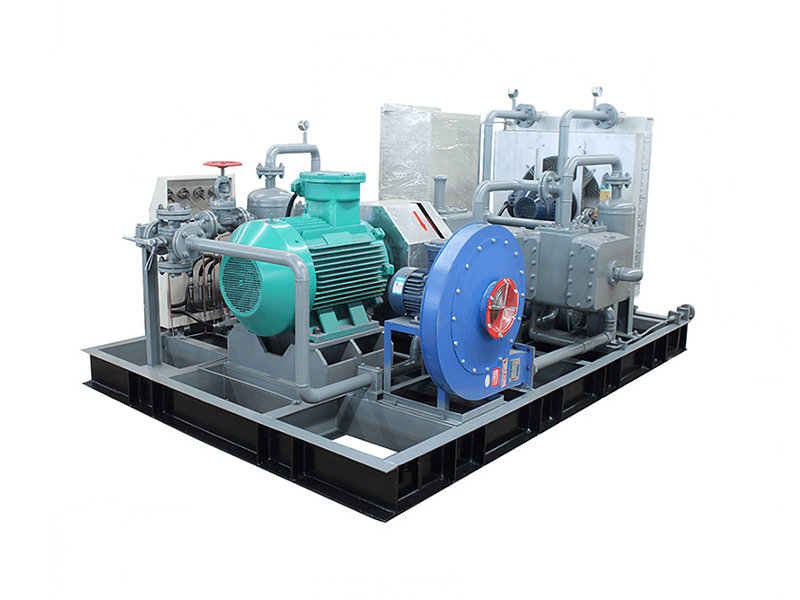

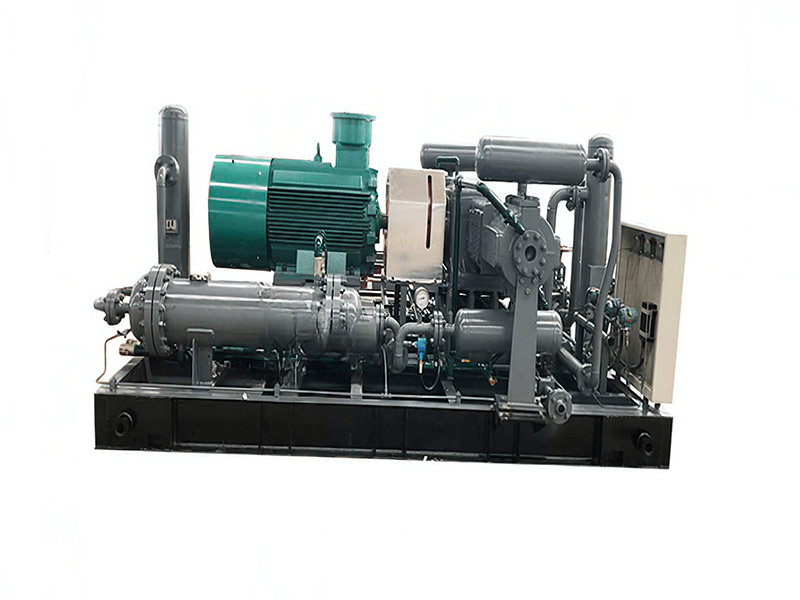

5. Cooling System: Reciprocating piston compressors generate heat during the compression process. To maintain safe operating temperatures, chlorine compressors often include cooling systems, such as air or water cooling, to dissipate the heat and prevent overheating.

6. Gas Filtration: Chlorine gas may contain impurities or particulate matter that can impact compressor performance and cause damage. Reciprocating piston chlorine compressors may include gas filtration units to remove contaminants, ensuring the chlorine gas is clean and free from harmful substances.

7. Control and Monitoring System: Reciprocating piston chlorine compressors typically have control and monitoring systems to regulate and monitor key parameters such as pressure, temperature, and flow rate. These systems may utilize sensors, gauges, and control panels to provide real-time information to the operator and ensure proper operation.

8. Maintenance and Service: Regular maintenance and service are crucial for the reliable and efficient operation of reciprocating piston chlorine compressors. This includes periodic inspections, lubrication, seal replacements, and adherence to manufacturer-recommended maintenance schedules.

9. Compliance with Regulations: Reciprocating piston chlorine compressors must comply with applicable safety standards and regulations for chlorine gas handling, storage, and emissions control. Complying with these regulations ensures the safe and responsible operation of the compressor system.

10. Capacity and Pressure Range: Reciprocating piston chlorine compressors are available in different capacity and pressure ranges to accommodate various applications. The capacity refers to the volume of gas compressed per unit of time, while the pressure range indicates the maximum pressure the compressor can achieve.

11. Multiple Stages: To achieve higher pressures, reciprocating piston chlorine compressors may employ multiple stages. Each stage consists of a cylinder and piston assembly, with the gas being compressed in successive stages to reach the desired pressure. Intercoolers or aftercoolers may be included between stages to remove heat and improve efficiency.

12. Variable Speed Drive: Some reciprocating piston compressors may incorporate a variable speed drive, allowing for precise control of the compressor's speed and output. This feature enables efficient operation by adjusting the compressor's capacity to match the demand, reducing energy consumption and wear on the equipment.

13. Start-Up and Shutdown Procedures: Reciprocating piston chlorine compressors require specific start-up and shutdown procedures to ensure safe and reliable operation. These procedures typically include proper priming, purging of air or non-condensable gases, and gradual ramp-up or ramp-down of compressor speed and pressure.

14. Noise and Vibration Control: Reciprocating piston compressors can generate significant noise and vibrations during operation. Manufacturers may incorporate measures to reduce noise and vibrations, such as vibration dampening mounts, acoustic enclosures, or insulation materials to minimize noise levels and enhance operator comfort.

15. Remote Monitoring and Control: Some reciprocating piston chlorine compressors may offer remote monitoring and control capabilities. This feature allows operators to monitor the compressor's performance, receive real-time alerts or notifications, and adjust settings remotely, enhancing operational efficiency and convenience.

It's important to note that the specific features of reciprocating piston chlorine compressor may vary depending on the manufacturer, model, and application. Consulting the manufacturer's documentation and guidelines specific to the compressor model being used is essential for understanding the precise features and capabilities of the equipment.

Price range of reciprocating piston chlorine compressors

The price range of reciprocating piston chlorine compressors can vary depending on several factors, including the compressor's capacity, pressure rating, construction materials, brand reputation, and additional features. It's important to note that specific pricing information may change over time and can vary among manufacturers and suppliers. Additionally, customizations or specialized requirements may affect the overall cost.

As a rough estimate, reciprocating piston chlorine compressors can range in price from several thousand dollars for smaller or lower-capacity models to tens of thousands or even hundreds of thousands of dollars for larger, high-capacity compressors with advanced features.

It's recommended to reach out to manufacturers or authorized distributors for accurate and up-to-date pricing information based on your specific requirements. They can provide detailed quotes and further assist you in selecting a compressor that suits your needs while considering your budget.