Wellhead gas refers to natural gas that is produced directly from a wellhead, which is the initial point of extraction at an oil or gas well. It is the gas that comes out of the ground along with oil or independently in gas wells.

When a well is drilled and reaches a natural gas reservoir, the pressure in the reservoir forces the gas to flow up the wellbore to the surface. At the wellhead, the wellhead gas is separated from any associated liquids, such as oil or water, and processed to remove impurities and prepare it for transportation and distribution.

Wellhead gas typically consists primarily of methane (CH4), which is the main component of natural gas. However, it can also contain other hydrocarbons such as ethane, propane, butane, and small amounts of non-hydrocarbon gases like carbon dioxide (CO2), nitrogen (N2), and hydrogen sulfide (H2S). The specific composition of wellhead gas varies depending on the geological formation and location of the well.

Once the wellhead gas is processed and treated to meet pipeline specifications, it can be transported through pipelines for distribution to consumers or used for various applications such as electricity generation, heating, industrial processes, and as a feedstock for petrochemical industries.

Wellhead gas plays a significant role in the energy industry as a cleaner-burning alternative to coal and oil, and it is an important source of fuel for many countries around the world.

About wellhead gas compression

Wellhead gas compression refers to the process of compressing natural gas at the wellhead or near the production site. It involves the use of compressors to increase the pressure of the gas, making it easier to transport and process.

When natural gas is extracted from the well, it typically has relatively low pressure. Wellhead gas compression is employed to raise the gas pressure to a level suitable for transportation through pipelines or for further processing. Compression is necessary to overcome pressure drop and frictional losses that occur as the gas flows through gathering lines, processing facilities, or transmission pipelines.

Wellhead gas compression offers several benefits:

1. Pressure Maintenance: Compression helps maintain the pressure at the wellhead, ensuring a steady and consistent flow of gas. This is particularly important in situations where the reservoir pressure is declining, which can happen as the natural gas field matures.

2. Enhanced Production: Higher pressure at the wellhead due to compression can increase the flow rate of gas, leading to higher production volumes. By maintaining adequate pressure, wellhead gas compression optimizes production and maximizes the recovery of natural gas from the reservoir.

3. Efficiency Improvement: Compression reduces the volume of gas, making it more efficient for transportation. Compressing the gas at the wellhead reduces the need for additional compression along the pipeline network, minimizing energy losses and associated costs.

4. Preventing Backflow: Gas compression at the wellhead helps prevent the backflow of liquids, such as water or condensates, into the wellbore. By maintaining a higher pressure, the compressor ensures that liquids are kept out of the production system, preserving the integrity of the well and avoiding potential damage.

5. Gas Treatment Support: Wellhead gas compression can be combined with gas treatment equipment, such as separators or dehydrators, to enhance their performance. The higher pressure provided by the compressor aids in the separation of liquids and removal of impurities from the gas stream, improving the quality of the gas.

6. Flexibility and Adaptability: Wellhead gas compression systems can be designed to accommodate varying gas flow rates and pressures, allowing for flexibility in production operations. They can be adjusted or expanded as production conditions change or new wells are brought online.

How to compress wellhead gas

Compressing wellhead gas involves a series of steps and considerations. Here's a general overview of the process:

1. Determine Compression Requirements: Assess the specific requirements for compressing the wellhead gas based on factors such as the gas flow rate, desired outlet pressure, gas composition, and operational conditions. This information will help in selecting the appropriate compressor type and size.

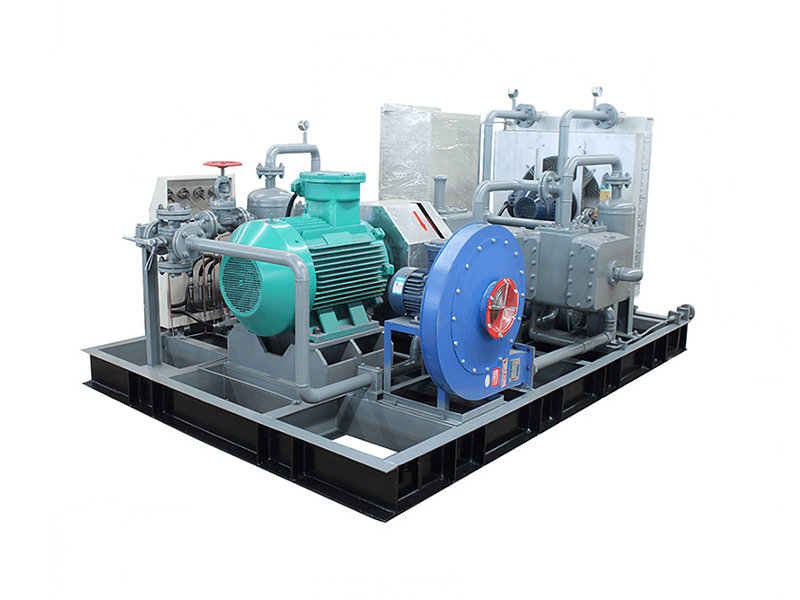

2. Select the Compressor: Choose a compressor type suitable for wellhead gas compression. Common options include reciprocating compressors, centrifugal compressors, and rotary screw compressors. Consider factors such as efficiency, reliability, maintenance requirements, and compatibility with the gas composition.

3. Design the Compression System: Design the wellhead gas compression system, including the necessary piping, valves, and instrumentation. Consider the layout, space constraints, safety requirements, and integration with other equipment in the production system.

4. Install the Wellhead Gas Compressor: Ensure proper installation of the compressor according to the manufacturer's guidelines and industry best practices. This includes proper alignment, mounting, and connection of inlet and outlet pipes. Consider factors such as vibration isolation, foundation requirements, and accessibility for maintenance.

5. Provide Intake Filtration: Install appropriate intake filters to prevent contaminants such as dust, debris, and liquids from entering the compressor. This helps protect the compressor internals and ensures reliable operation.

6. Control and Monitoring: Install control and monitoring systems to regulate and optimize compressor operation. This includes instrumentation for measuring and controlling parameters such as pressure, temperature, and speed. Implement safety features such as emergency shutdown systems and pressure relief valves.

7. Regular Maintenance: Establish a maintenance program to ensure the compressor operates efficiently and reliably. This includes routine inspections, lubrication, filter replacement, and periodic checks of critical components. Adhere to the manufacturer's maintenance guidelines and schedule.

8. Safety Considerations: Implement safety measures to protect personnel, equipment, and the environment. This includes implementing safety interlocks, gas detection systems, and emergency shutdown systems. Train personnel on safe operation, emergency procedures, and the handling of hazardous materials.

9. Performance Optimization: Continuously monitor and optimize the compressor's performance. Analyze operating data, identify opportunities for efficiency improvement, and implement measures such as variable speed drives, control systems, or energy-saving technologies to optimize energy consumption.

10. Compliance with Regulations: Ensure compliance with applicable regulations and standards related to wellhead gas compression, including environmental regulations, safety codes, and industry guidelines.

It's important to note that the specific details of wellhead gas compression can vary depending on site-specific conditions, gas composition, and operational requirements. Consulting with experienced engineers and professionals knowledgeable in gas compression systems can provide further guidance and assistance tailored to your specific situation.

How the wellhead gas compressor works

A wellhead gas compressor works by taking in the low-pressure gas from the wellhead and compressing it to a higher pressure. The compressed gas is then sent for further processing, transportation, or storage. Here's a simplified explanation of how a wellhead gas compressor operates:

1. Gas Intake: The wellhead gas compressor is connected to the wellhead or the gathering system, where the low-pressure gas is received. The gas enters the compressor through an inlet pipe.

2. Compression Chamber: Inside the compressor, there is a compression chamber where the gas is compressed. The compression chamber contains a piston (in the case of reciprocating compressors) or rotating impellers (in the case of centrifugal compressors) that create pressure by reducing the volume of the gas.

3. Gas Compression: As the piston or impellers move, the gas is compressed. In reciprocating compressors, the piston moves back and forth, drawing in the gas during the suction stroke and then compressing it during the compression stroke. In centrifugal compressors, the rotating impellers accelerate the gas, increasing its pressure.

4. Cooling and Lubrication: During compression, the gas temperature rises. To prevent overheating and damage to the compressor, a cooling system is employed. This can involve the use of cooling fins, water jackets, or separate cooling systems to remove excess heat. Lubrication systems ensure smooth operation and reduce friction between moving parts.

5. Discharge: Once the gas is compressed to the desired pressure, it is discharged from the compressor through an outlet pipe. The high-pressure gas is then directed towards the next stage of the production or transportation process, such as a processing facility or transmission pipeline.

6. Control and Monitoring: Wellhead gas compressors are equipped with control and monitoring systems to regulate and optimize their operation. These systems can include instrumentation to measure and control parameters such as pressure, temperature, and speed. They can also incorporate safety features, such as emergency shutdown systems and pressure relief valves.

7. Maintenance and Servicing: Regular maintenance and servicing of the wellhead gas compressor are essential to ensure its reliable and efficient operation. This includes periodic inspections, lubrication of moving parts, replacement of filters, and monitoring of performance indicators.

It's important to note that different types of compressors, such as reciprocating, centrifugal, or rotary screw compressors, have variations in their operation and internal mechanisms. The specific design and operation of a wellhead gas compressor depend on the chosen compressor type, gas flow rate, pressure requirements, and other site-specific considerations.