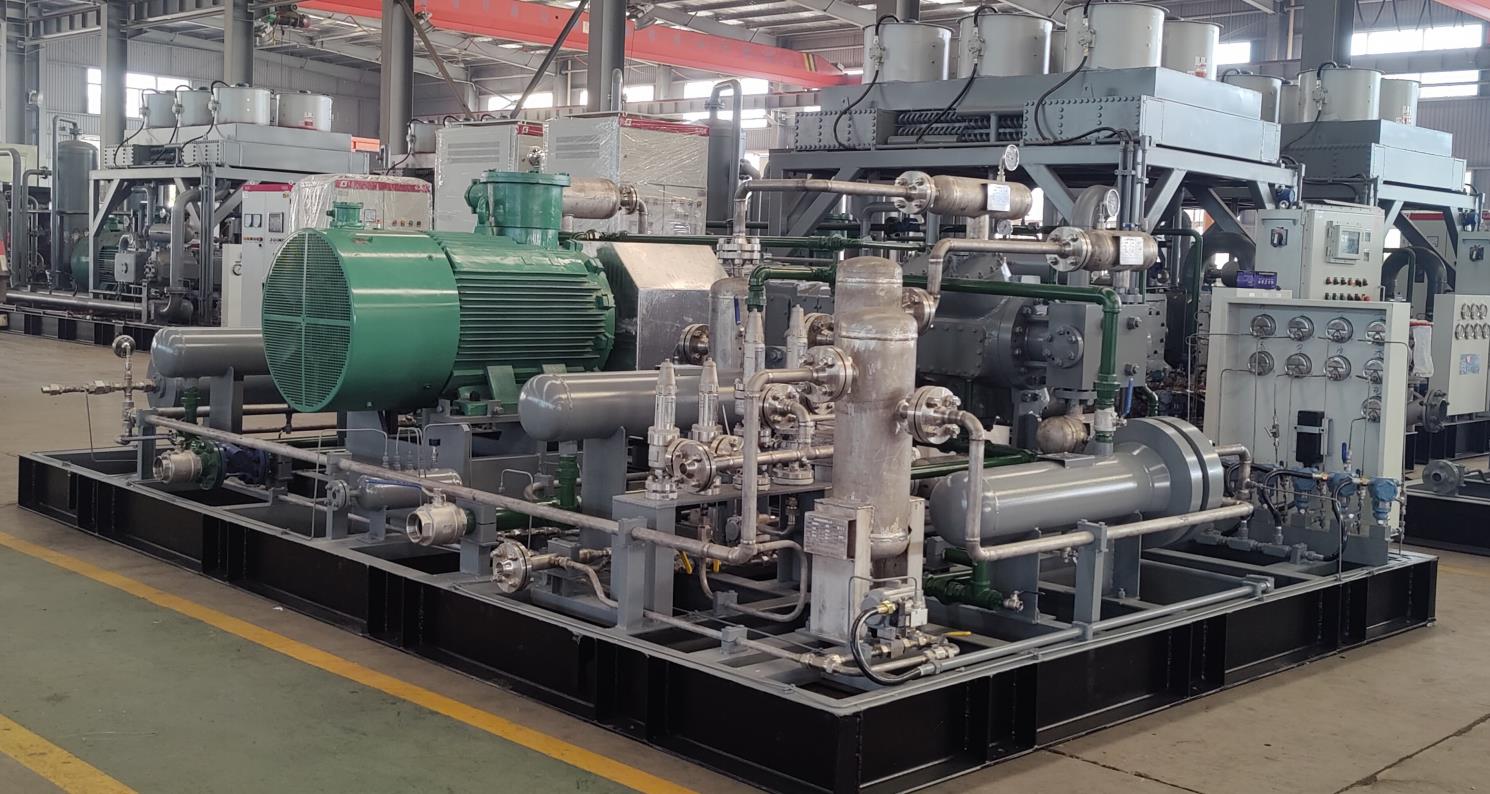

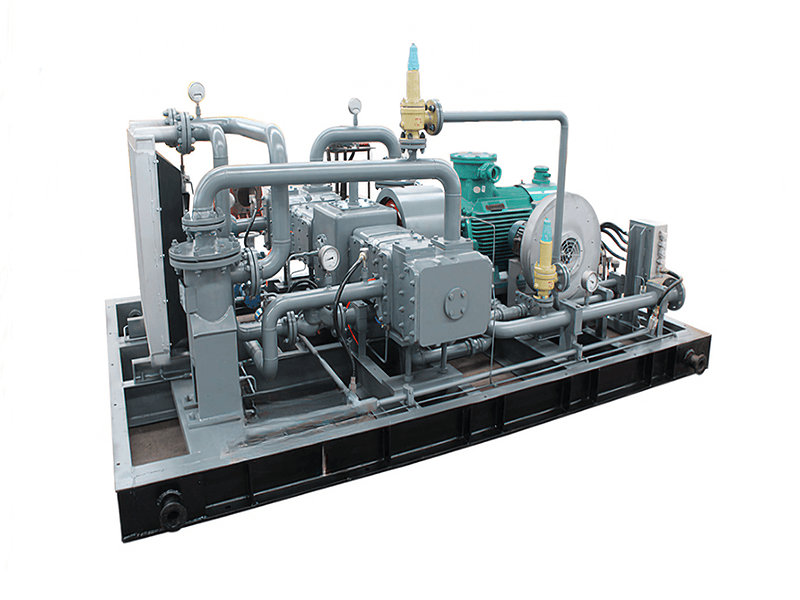

A chlorine compression system is designed to handle and compress chlorine gas for various industrial applications. The system typically consists of several key components:

1. Chlorine Source: The chlorine source is the starting point of the system, which can be a chlorine storage tank or cylinder. Chlorine is typically stored in pressurized containers, such as cylinders or ton containers, and it is important to follow proper safety protocols for handling and storage.

2. Chlorine Inlet and Piping: The chlorine gas is fed into the compression system through an inlet. The piping system connects the chlorine source to the compressor and ensures a smooth flow of gas.

3. Chlorine Compressor: The compressor is the central component of the chlorine compression system. It takes in the chlorine gas and compresses it to the desired pressure level. Reciprocating compressors or centrifugal compressors are commonly used for chlorine compression.

- Reciprocating Compressor: A reciprocating compressor uses a piston and cylinder arrangement to compress the chlorine gas. It operates by reciprocating motion, where the piston moves back and forth to compress the gas.

- Centrifugal Compressor: A centrifugal compressor uses rotating impellers to accelerate the chlorine gas and convert its kinetic energy into pressure energy. It is particularly suitable for high-pressure applications.

4. Intercoolers and Aftercoolers: Intercoolers and aftercoolers are heat exchangers located between the stages of a multi-stage compressor or after the final stage. They help remove heat generated during compression, ensuring that the compressed chlorine gas is cooled and its temperature is controlled.

5. Cooling System: A cooling system is employed to maintain the temperature of the compressor and prevent overheating. It usually involves a cooling water circuit or air cooling system, which helps dissipate heat generated during compression.

6. Safety Devices: Various safety devices are incorporated into the chlorine compression system to protect against potential hazards, such as leaks or overpressure situations. These devices may include pressure relief valves, rupture discs, gas detectors, emergency shutdown systems, and other safety mechanisms.

7. Discharge Piping and Outlet: The compressed chlorine gas is discharged from the compressor through a discharge piping system. The outlet may lead to further processing or distribution, depending on the specific application.

8. Gas/Liquid Separators: Chlorine compression systems may include gas/liquid separators to remove any liquid chlorine or condensate that may have formed during compression. These separators help ensure that only gaseous chlorine is delivered downstream for further processing or distribution.

9. Filtration Systems: Filtration systems are used to remove any particulate matter or impurities from the chlorine gas stream. This helps protect downstream components from potential damage and ensures the purity of the compressed chlorine gas.

10. Pressure Regulation System: A pressure regulation system is often incorporated into the chlorine compression system to control the discharge pressure of the compressed chlorine gas. This system may include pressure control valves, pressure gauges, and other instruments to maintain the desired pressure level.

11. Instrumentation and Control System: An instrumentation and control system is essential for monitoring and controlling various parameters of the chlorine compression system. This system may include sensors, transmitters, controllers, and human-machine interface (HMI) devices to ensure safe and efficient operation.

12. Emergency Shutdown System: An emergency shutdown system is crucial for quickly stopping the chlorine compression system in case of a safety or operational emergency. This system may include emergency stop buttons, alarms, and safety interlocks to initiate a safe shutdown procedure.

13. Ventilation and Exhaust System: Given the hazardous nature of chlorine gas, proper ventilation and exhaust systems are essential to ensure the safe dispersion of any chlorine gas leaks or releases. These systems help maintain a safe working environment and prevent the buildup of chlorine gas concentrations.

14. Monitoring and Alarm Systems: Monitoring systems, including gas detectors and leak detection sensors, are employed to continuously monitor the chlorine gas concentration in the system. If abnormal levels are detected, alarm systems are activated to alert operators and initiate appropriate safety measures.

15. Maintenance and Inspection Equipment: Chlorine compression systems require regular maintenance and inspection to ensure their safe and reliable operation. This may involve the use of specialized equipment such as inspection cameras, leak detection devices, and tools for equipment servicing.

Price range of a chlorine compression system

The price range of a chlorine compression system can vary depending on several factors such as the capacity, design, specifications, and additional features required. It's important to note that chlorine compression systems are typically customized to meet specific project requirements, and the prices can vary significantly based on those requirements.

As a rough estimate, a chlorine compression system can range from tens of thousands of dollars to several hundred thousand dollars or more. Larger capacity systems or those with specialized features may fall on the higher end of the price range. Additionally, factors such as the complexity of the system, installation requirements, safety measures, and any necessary infrastructure modifications can also contribute to the overall cost.

To obtain an accurate and up-to-date price for a chlorine compression system tailored to your specific needs, it is recommended to consult with reputable equipment manufacturers, suppliers, or engineering firms who specialize in chlorine compression systems. They can provide detailed quotes based on your project specifications and requirements.