A chlorine compression system is designed to compress chlorine gas for various industrial applications. It typically consists of several key components that work together to facilitate the compression process and ensure the safe handling of chlorine gas. Here are the main components of a chlorine compression system:

1. Chlorine Gas Source: The system begins with a reliable source of chlorine gas, such as chlorine cylinders or a bulk storage tank. Chlorine gas is obtained from the source and directed into the compression system.

2. Chlorine Gas Inlet: The chlorine gas enters the compression system through an inlet connection. This connection is designed to provide a secure and leak-free interface between the gas source and the system.

3. Gas Filters: Gas filters are installed in the system to remove impurities, particulates, and moisture present in the chlorine gas stream. These filters help protect the downstream components and ensure the quality of the compressed gas.

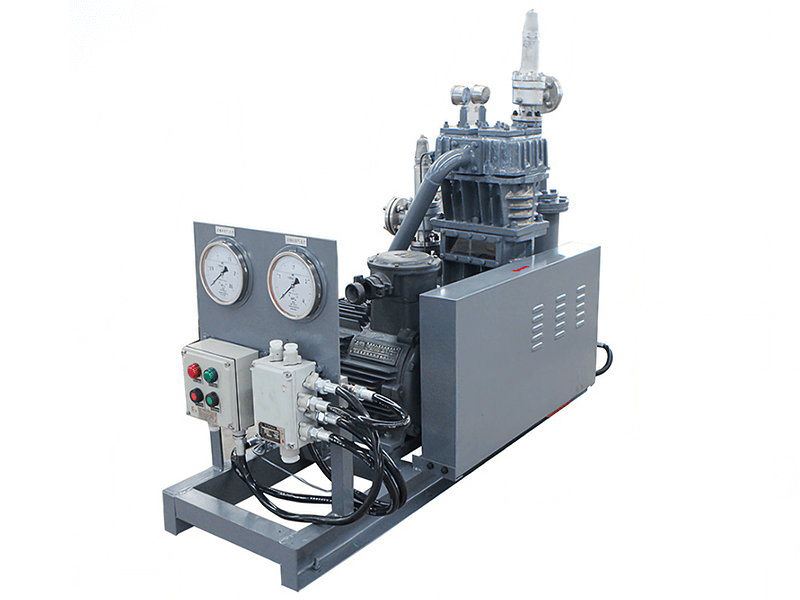

4. Gas Compressor: The chlorine compressor is the central component of the chlorine compression system. It is responsible for compressing the chlorine gas to the desired pressure level. Typically, a reciprocating or centrifugal compressor is used for this purpose, depending on the specific requirements of the application.

5. Compressor Drive: The compressor drive system provides the power required to drive the gas compressor. It can be an electric motor, a natural gas engine, or another type of prime mover, depending on the availability of energy sources and the specific needs of the system.

6. Cooling System: Compression generates heat, so a cooling system is essential to maintain the compressor's temperature within safe operating limits. This system typically includes coolers, heat exchangers, or water cooling circuits to dissipate the heat generated during compression.

7. Pressure Relief Devices: Pressure relief devices, such as pressure relief valves, are installed in the system to protect against overpressure conditions. These devices automatically release excess pressure from the system to prevent any potential damage or safety hazards.

8. Pressure Gauges and Instruments: Pressure gauges and instruments are installed at various points in the system to monitor and display the compression process parameters, such as inlet pressure, outlet pressure, and system temperature. These instruments help operators ensure the system operates within safe and optimal operating ranges.

9. Safety Systems: A chlorine compression system incorporates various safety features and systems to protect against potential hazards associated with handling chlorine gas. These safety systems may include gas leak detection sensors, gas detection alarms, emergency shutdown systems, and ventilation systems to maintain a safe working environment.

10. Gas Outlet: The compressed chlorine gas is directed to the desired application or storage location through a gas outlet connection. This connection ensures the controlled and safe transfer of the compressed gas to its intended destination.

It's important to note that the specific configuration and components of a chlorine compression system may vary depending on the capacity, pressure requirements, and safety standards of the application. Compliance with applicable industry standards and regulations is crucial to ensure the safe operation of the system.

Cost range of a chlorine compression system

The cost range of a chlorine compression system can vary significantly depending on several factors, including the capacity, pressure requirements, specific design features, and any additional safety measures or customization required for the application. Other factors that may influence the cost include the supplier, geographical location, and market conditions.

The cost range for a chlorine compression system can typically range from tens of thousands to several hundred thousand dollars. Larger systems with higher capacities and pressures, along with additional safety features, tend to be more expensive.

Here are a few examples of estimated cost ranges for different types of chlorine compression systems:

1. Small-Scale Chlorine Compression System:

- Capacity: 100-500 kg/day

- Pressure: 5-10 bar

- Cost Range: $30,000 - $80,000

2. Medium-Scale Chlorine Compression System:

- Capacity: 500-2,000 kg/day

- Pressure: 10-20 bar

- Cost Range: $80,000 - $200,000

3. Large-Scale Chlorine Compression System:

- Capacity: 2,000-10,000 kg/day

- Pressure: 20-30 bar

- Cost Range: $200,000 - $500,000

It's important to note that the initial equipment cost is not the only consideration when evaluating the total cost of a chlorine compression system. Other factors such as installation, commissioning, ongoing maintenance, and operational costs should also be taken into account. Additionally, compliance with safety standards and regulations may require additional investments in safety systems and controls, which can impact the overall cost.

To get a more accurate cost estimate for a specific chlorine compression system, it is recommended to consult with equipment suppliers, manufacturers, or engineering firms specialized in gas compression systems. They can provide detailed quotations and take into account the specific requirements and parameters of your project.