【孟若羽天美传mv免费观看】最新入口

-

The advantages and disadvantages of various cooling methods for Natural Gas Compressors

Jun 16, 2024 -

What should we do if the chlorine compressor is corroded

Jul 03, 2024 -

Applications of rich gas recovery

Jun 04, 2024 -

Cng Substation Compressors Prices And Manufacturers

Apr 11, 2024 -

Compression of Ammonia and Application of Compressed Ammonia

Jul 23, 2024 -

The working principles of chlorine gas compressor

May 24, 2024

孟若羽天美传mv免费观看【乾坤易变】Jun 22, 2024

by:Anhui Shengnuo Compressor Manufacturing Co.,Ltd

Follow Us:

Boil-off gas (BOG) refers to the gaseous form of a cryogenic liquid that is generated when the liquid undergoes a phase change from its low-temperature liquid state to a higher-temperature gaseous state. This phase change occurs when the cryogenic liquid, typically stored at extremely low temperatures, absorbs heat from the surrounding environment.

However, even with the best insulation and storage techniques, heat from the surroundings slowly enters the storage system, causing a portion of the cryogenic liquid to vaporize and become boil-off gas. This boil-off gas is typically a mixture of the vaporized gas, as well as any other impurities or components present in the original liquid.

Boil-off gas poses several considerations and challenges in cryogenic systems, including:

1. Pressure Build-Up: The generation of boil-off gas leads to an increase in pressure within the storage vessel or transportation system. This pressure build-up needs to be managed to prevent over-pressurization and potential safety hazards.

2. Loss of Product: Boil-off gas represents a loss of the cryogenic liquid itself, which can be undesirable from an economic standpoint. Minimizing boil-off gas generation and effectively utilizing or capturing the gas can help reduce product losses.

3. Thermal Management: Managing the heat influx and controlling the temperature within the storage or transportation system is crucial to minimize boil-off gas generation. Effective insulation, refrigeration systems, and heat transfer management techniques are employed to mitigate excessive boil-off.

4. Gas Handling and Utilization: Boil-off gas needs to be properly handled, managed, and potentially utilized to prevent its release into the environment. It can be re-liquefied, used as fuel for power generation or heating, or re-injected back into the storage system.

The management of boil-off gas is a critical aspect of cryogenic systems, especially in industries where the storage and transportation of liquefied gases are involved. Various technologies and strategies are employed to minimize boil-off gas generation, optimize its utilization, and ensure the safe and efficient operation of cryogenic systems.

【孟若羽天美传mv免费观看】注册登录

The types of boil-off gas can vary depending on the specific liquefied gas being stored or transported. Here are some common types of boil-off gas associated with different liquefied gases:

1. LNG Boil-Off Gas: LNG boil-off gas primarily consists of methane, which is the main component of natural gas. It can also contain small amounts of other hydrocarbons such as ethane, propane, and butane, as well as impurities like nitrogen, carbon dioxide, and traces of water vapor.

2. LPG Boil-Off Gas: LPG boil-off gas is typically a mixture of propane and butane gases. The exact composition of the boil-off gas can vary depending on the specific blend of propane and butane in the liquefied petroleum gas. It may also contain traces of other hydrocarbons and impurities.

3. Liquid Nitrogen Boil-Off Gas: Boil-off gas from liquid nitrogen primarily consists of nitrogen gas (N2) since it is the main component of liquid nitrogen. However, depending on the production process and any impurities present, the boil-off gas may also contain small amounts of oxygen, argon, carbon dioxide, and other trace gases.

4. Other Liquefied Gases: Boil-off gas from other liquefied gases, such as ethylene, propylene, ammonia, or carbon dioxide, will have compositions specific to the particular gas being stored or transported. The boil-off gas may consist primarily of the gas itself or include other components depending on the composition and impurities present in the original liquefied gas.

It's important to note that the composition of the boil-off gas may change over time due to factors such as temperature fluctuations, pressure changes, and the presence of impurities. Gas handling and management systems are designed to handle and treat boil-off gas to ensure its safe handling, utilization, or re-liquefaction when necessary.

The specific composition and handling of boil-off gas are critical considerations for the design and operation of storage and transportation systems to ensure safety, efficiency, and environmental compliance.

Boil-off gas is commonly associated with the storage and transportation of liquefied gases such as LNG, LPG, and liquid nitrogen due to the nature of these gases and the extreme temperatures at which they are stored. These gases are cooled and liquefied to facilitate storage and transportation in a more compact form.

1. Liquefied Natural Gas (LNG): LNG is natural gas that has been cooled to extremely low temperatures, typically around -162 degrees Celsius (-260 degrees Fahrenheit), to convert it into a liquid state for easier storage and transportation. However, even with advanced insulation techniques, some heat from the surroundings slowly enters the storage tanks, causing the LNG to vaporize and generate boil-off gas.

2. Liquefied Petroleum Gas (LPG): LPG consists of propane and/or butane and is also stored and transported in a liquefied state under pressure. Like LNG, LPG is stored at low temperatures, typically ranging from -42 degrees Celsius (-44 degrees Fahrenheit) to -188 degrees Celsius (-306 degrees Fahrenheit). Heat ingress into the storage tanks leads to the evaporation of the LPG, resulting in the generation of boil-off gas.

3. Liquid Nitrogen: Liquid nitrogen is produced by cooling and condensing nitrogen gas to extremely low temperatures, around -196 degrees Celsius (-321 degrees Fahrenheit), which causes it to become a liquid. However, even with efficient insulation techniques, heat transfer occurs, causing the liquid nitrogen to boil off and generate gas.

The extreme temperatures at which these liquefied gases are stored require specialized storage vessels and transportation systems with robust insulation to minimize heat ingress. Despite these measures, some amount of heat still enters the system, leading to the vaporization and generation of boil-off gas.

Efficient management of the boil-off gas is crucial to prevent pressure buildup, minimize product losses, and ensure the safe and efficient operation of storage and transportation systems for these liquefied gases. Various techniques, such as insulation, refrigeration, and utilization of the gas, are employed to mitigate boil-off and maximize the efficiency of these processes.

【孟若羽天美传mv免费观看】平台地址

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

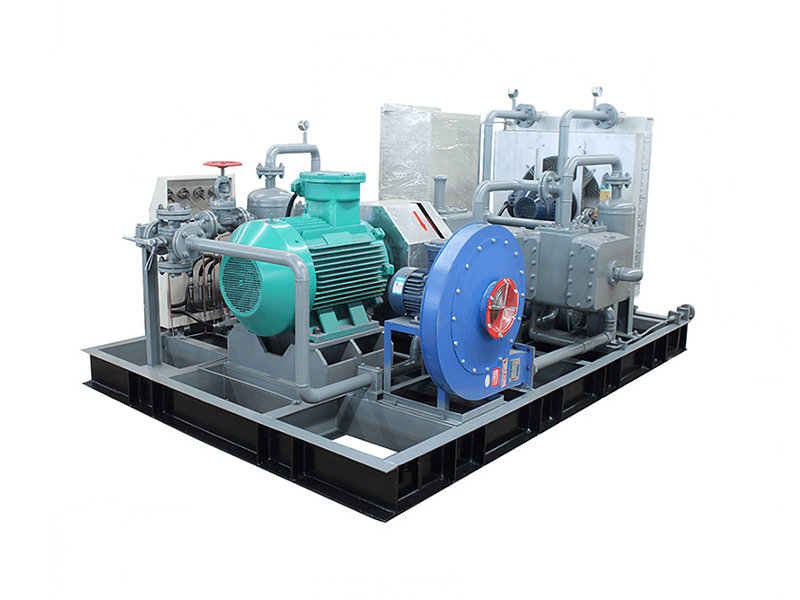

Since its establishment, ASC Compressor has focused on comprehensive solutions for Oilfield industry, CNG/LNG industry, Environmental protection, and Industrial compression. It has excellent quality in designing, researching, producing and manufacturing.

- Quick Link > Home > Products > Applications > News > About > Contact

-

Contact Us

- E-Mail: [email protected]

- Tel: +8618098536798/+86(0)5633698699

- Fax: +86(0)5633698699

-

Address:

No. 17 Xingye Road, Economic Development Zone, Xuanzhou District, Xuancheng City, Anhui Province, China